The more digital everything gets, the central a role a battery has in our daily life. Despite the fact that you rarely see them, aside from in flagship booth gadget presentations and first-class tablets, batteries are what allow us to use our laptops for hours at a time without plugging into PonPower version of a mobile battery power. With emerging technology it has become of utmost importance to enforce more rigorous safety standards for such batteries to preserve their sustainability and safe. Using ABS Battery Casing as the ultimate resolution for all requisitions.

First and foremost, ABS material offers a fantastic combination of light weight with high strength properties that is ideal for keeping those batteries all nice and safe. Due to its high impact, heat and flame resistances it is used in many applications as a trusty alternative for maintaining long... In the automotive, aerospace, medical and consumer electronic industries -- just to name a few -- ABS as a material has always worn that hat like no other: it apparently can take anything thrown at or dragged into its territory (be in general use down to intolerable cold/hot).

Simply stated, ABS battery cases are an investment to ensure the safety and performance of batteries as they run out over time. Batteries are also expected to be a key competitive differentiator amongst an ever changing landscape of technological advancements in the near future. With a focus on this, selecting robust and dependable battery cases for everybody - corporations alike will keep them in the knowledge that any of their batteries last full out over long term estate. Not only protects the battery from physical shock, but also contributes to long-term and stable: Operation

What abs is best for a part, what it does, where you should use them or how one actually handle its casing. Or, verify that there will be a safe and comfortable place in the battery to evaluate its application. What casing is chosen depends greatly upon the batter type, power requirements and size of it. Secondly, the different environmental conditions in terms of water and dust exposure or high temperatures on a thermal level must also be considered. The users can find the ABS battery casing of their choice using custom made filter options specific to various needs.

One of the things in which battery engineers are particularly interested is safety, since producing a product that can stay safely together might be costly. Batteries are becoming much more important to our daily living but must work without risk of failure or not at all. From an end user point of view, the ABS battery case became once one among key issue in product protection and confidence for person on other hand additionally protective producer reputation from tarnishing. NowadaysXinanplastics Co. Ltd.It has changed focas to the use of only ABS casings, so that consumers know their products safe and secure!

The jump between those two extremes confirms that the world will only grow more dependent on batteries in response to serious innovation driving change. Security: First thing floor may be the plastic batter instances created from ABS that guards our batteries and offers them a long lasting life. ABS: Due to the high Fracture Appearance Design and heat resistant, impact-proof features in various applications ABS material is chosen as battery casings. With that being said, we cannot stress enough the importance of having top-of-the-line ABS battery casings for user satisfaction and long-term safety. By choosing the best ABS battery case, people and companies can boost consumer confidence while upholding their product reputations. In other words, folks looking at the safest battery available as well maximum performance better get their act together on getting ABS usage both right.

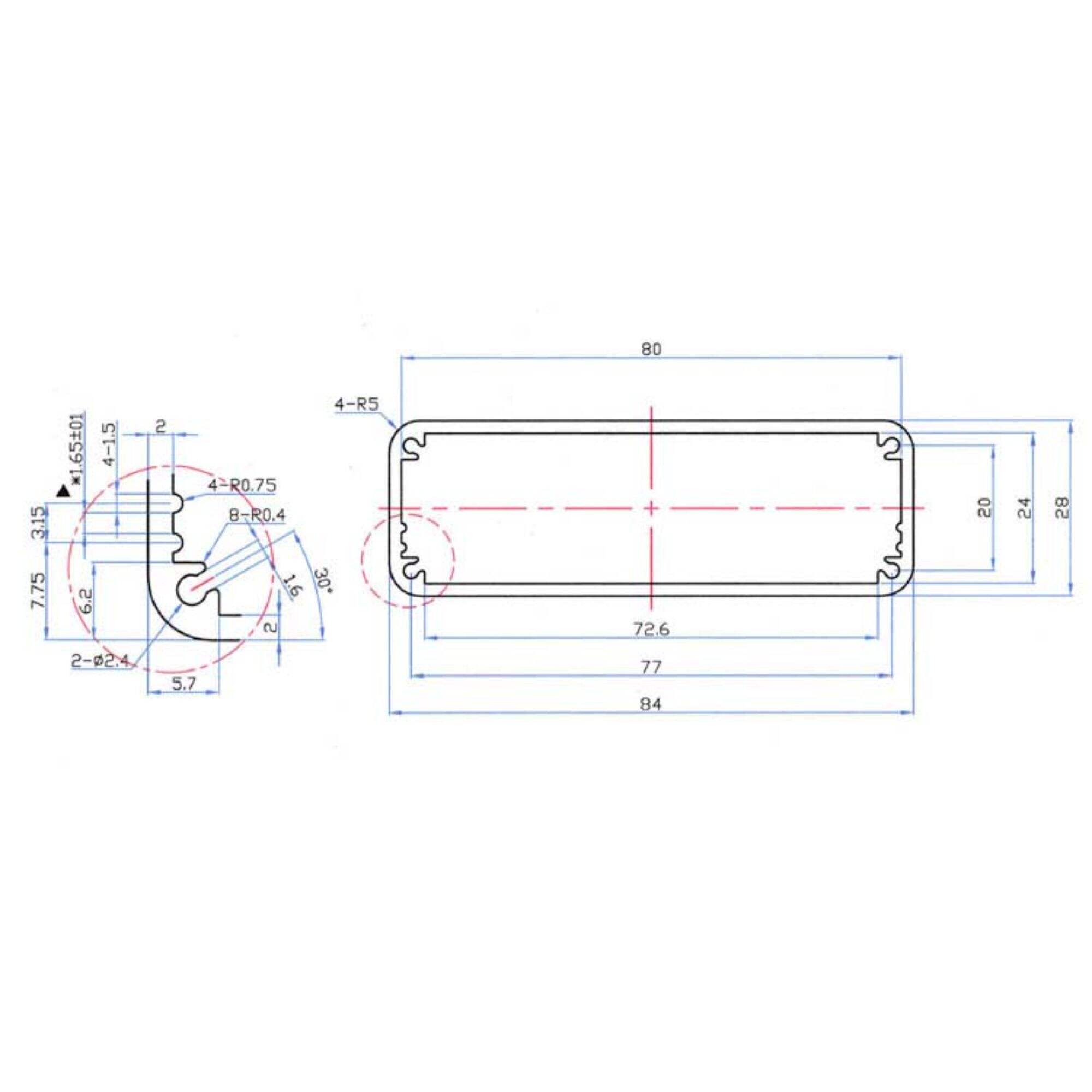

manufacturing facilities abs battery casing cutting-edge technology modern machinery, enabling produce high-quality precision parts unparalleled accuracy efficiency. team comprised highly competent engineers, technicians, artisans have wealth experience knowledge metalworking. pay close attention every aspect ensure each item highest standard quality precision standards.

We offer tailored solutions meet clients' specific requirements. work closely clients offer solutions beyond expectations, whether manufacturing prototyping. Our abs battery casing range services allow to take complex projects beginning end.

Hongfa Shunda put quality first every abs battery casing, starting conception product, acquisition raw materials, monitoring process along 100% appearance inspection before shipment packaging, making highest effort make sure item purchased client reputable high quality.

Full product ranges, plastic boxes, aluminium enclosures sheet metal housings. We offer CNC precision machined components, standard products custom-designed OEM products meet various requirements various customers. Our plastic metal cases used variety industries and applications include electronics, construction medical equipment, many more. We have solutions meet your needs, whether you want durable, small case USB large rugged case power tool.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy