As one of the industries that can be seen in most places, and with today's world selling plastic enclosures. One of their main uses is as cases that protect a variety of electronic components, machine parts and consumer goods. From a smooth cover for the surface of your phone to provide an effective shield against rugged and robust surroundings in outdoor equipment or just as inserts, Hongfa Shunda enclosure plastics are essential substances that help keep delicate internal components intact. The large plastic enclosure create the first impression in terms of visual appeal and functionality on what will one likely appreciate.

There is more that high-quality Hongfa Shunda enclosure plastics can provide besides solid protection. These technologies are critical for the durability, usability and market acceptance of products. Overall, all these materials of outdoor plastic enclosures are premium and built to last through hundreds of impacts, scratches as well as corrosive elements, making sure the device stays functional even in harsh conditions. In addition, they have very good insulating properties which protect electronics from shock and temperature changes. High-gloss or textured finishes also offer visual benefits that enhance product aesthetics, giving a professional appearance and sophisticated look consumers expect from business-grade products.

Customizing Hongfa Shunda enclosure plastics has reshaped product design landscape. This means that manufacturers can custom-build housings to meet the needs of their applications perfectly. Efficiency of plastic outdoor enclosure is maximized and assembly processes are made simpler by tailored dimensions, shapes or features like cable management systems and integrated mounting points. In addition to enabling use of custom-molded plastics, complex geometries can be incorporated as well branding elements that differentiate products in a crowded market. With advanced manufacturing methods like injection molding and 3D printing, prototypes can be created quickly to accelerate time-to-market endeavors while promoting innovation.

Outdoor settings pose unique challenges that must be kept in mind when selecting Hongfa Shunda enclosure plastics. UV exposure, drastic temperature changes, moisture and other wildlife-related elements all mean that the plastics used have to be able to endure these conditions. Most often used because of their high impact strength and weather ability, common choices are polycarbonate. Specifically, polycarbonate lends itself to high transparency accompanied with strong UV resistance - properties that find their purpose in visible applications; for instance-security camera housings or outdoor lighting. UV stabilizers are also used in Tapes, aiding long-term color stability and the longevity of the material. Reliability and durability are important to transparent plastic enclosure and to maintain an understanding of the use environment demands as well as plastic performance requirements.

The change towards sustainability has also led to the creation of eco-friendly enclosure plastics by Hongfa Shunda. Towards these, masses are leaning slowly in the market; recycled plastics, bio-based resins, and comfortable materials and much more. Post-consumer recycled (PCR) plastics are a sustainable alternative to enhance the cooling effect of an enclosure, which simultaneously reduces waste and resource consumption whilst allegedly performance neutral. Bio-based wall mount plastic enclosure made from corn starch and sugarcane have a lower carbon footprint, for example, but only under specific environmental conditions are these products biodegradable. While these green options might add initial cost premiums or some amount of loss in functionality, they reflex consumer's increasingly positive regard toward no harm products and contribute towards corporate social responsibility goals.

team made up highly-skilled engineers, technicians craftsmen years experience knowledge Enclosure plastic. pay attention every little detail ensure product exceeds highest quality high-precision standards

Hongfa Shunda puts product's top-quality first, beginning design process, purchasing raw materials, observing step process, Enclosure plastic inspection appearance before packaging shipping.

We tailor solutions Enclosure plastic clients' particular requirements. Whether it's prototyping, manufacturing, assembly, work closely clients deliver solutions meet exceed expectations. CNC laser cutting machining, welding sheet metal fabrication provide wide assortment manufacturing capabilities help various industries different applications. broad range services allow manage complex projects conception completion.

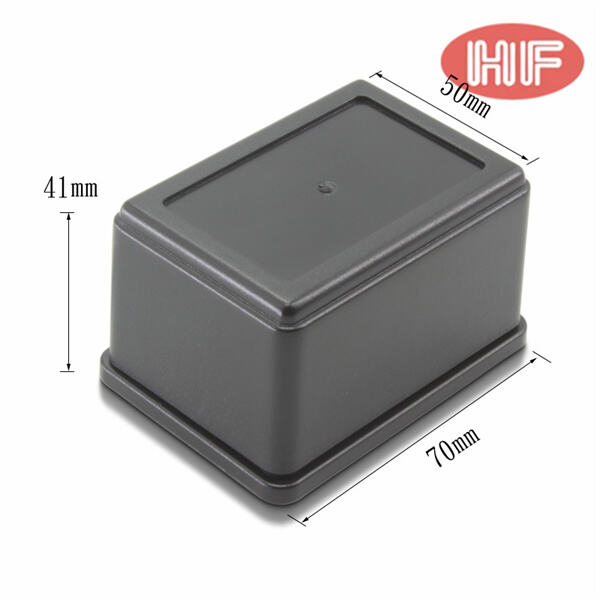

complete product line, ranging aluminium enclosures, sheet metal housings CNC precision machined components standard products OEM custom products, meet the various requirements various customers. Metal plastic cases utilized many industries applications including electronic equipment, construction medical equipment. Whether you need small robust durable case your USB big, rugged case power tools We have solution right you.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy