Medical device housings are crucial. They help ensure that medical equipment is safe and functions properly. Consider them a sort of armor. This shell protects all essential parts of the device from damage. We at Hongfa Shunda, have made robust and safe enclosures for countless medical devices.

Medical devices are things that help people feel better when they are sick or hurt. It’s crucial that these devices get it right every time. Here is where medical device enclosures come in. They help to keep the more sensitive parts of the device from becoming damaged or dirty. This is what enables the device to function as intended, and keeps people safe and healthy.

When we’re designing medical device enclosures, we give it a long thought as to how the device will be used. The canopy should also be easy to open and close – so doctors and nurses can access the sphyg-anometer in seconds in an emergency. It also has to be sturdy and safe enough to protect the device from accidents in busy hospitals.

The better technology gets, the better the medical device enclosures we design are made. At Hongfa Shunda, we are always on the hunt for new materials to improve and strengthen our enclosures. We have overalls out of light, easy-to-clean materials that resist germs and bacteria. This helps maintain that the medical devices are safe and clean for patients.

In hospitals and clinics, medical devices must abide by rigorous safety regulations to be used. That part is the enclosure materials. However, here at Hongfa shunda, we ensure that all our enclosures adhere to, or exceed these guidelines. This ensures our enclosures are safe to use and won’t injure patients or health care staff.

There are no two medical devices alike so the enclosure has to be custom to meet the exact specifications of the device. That means ensuring all of the buttons and screens are reachable, and that the device is easy to clean. Impact of financial crisis A family packing company owner, iframe," other people with Myopia considere, both private and government providers of infrastructure services to be more competitive and efficient.‡ 3 Pure oxygen and absolute air at T below 60°C and P above 101. This ensures that the gadget functions like new every time it is utilized.

We provide customized solutions satisfy customers' individual medical device enclosure. comes prototyping, machining, assembly, work close collaboration clients create solutions exceed expectations. From CNC laser cutting machining, sheet metal fabrication welding provide broad range manufacturing capabilities accommodate variety industries applications. manage complex projects beginning finalization, using full range service.

Hongfa Shunda puts product's top-quality first, beginning design process, purchasing raw materials, observing step process, medical device enclosure inspection appearance before packaging shipping.

manufacturing facilities medical device enclosure cutting-edge technology advanced machinery, enabling make high-quality precision components unmatched precision efficiency. team consists highly experienced engineers, technicians craftsmen who possess years experience expertise metalworking. pay close attention every single detail ensure product exceeds highest quality precise standards.

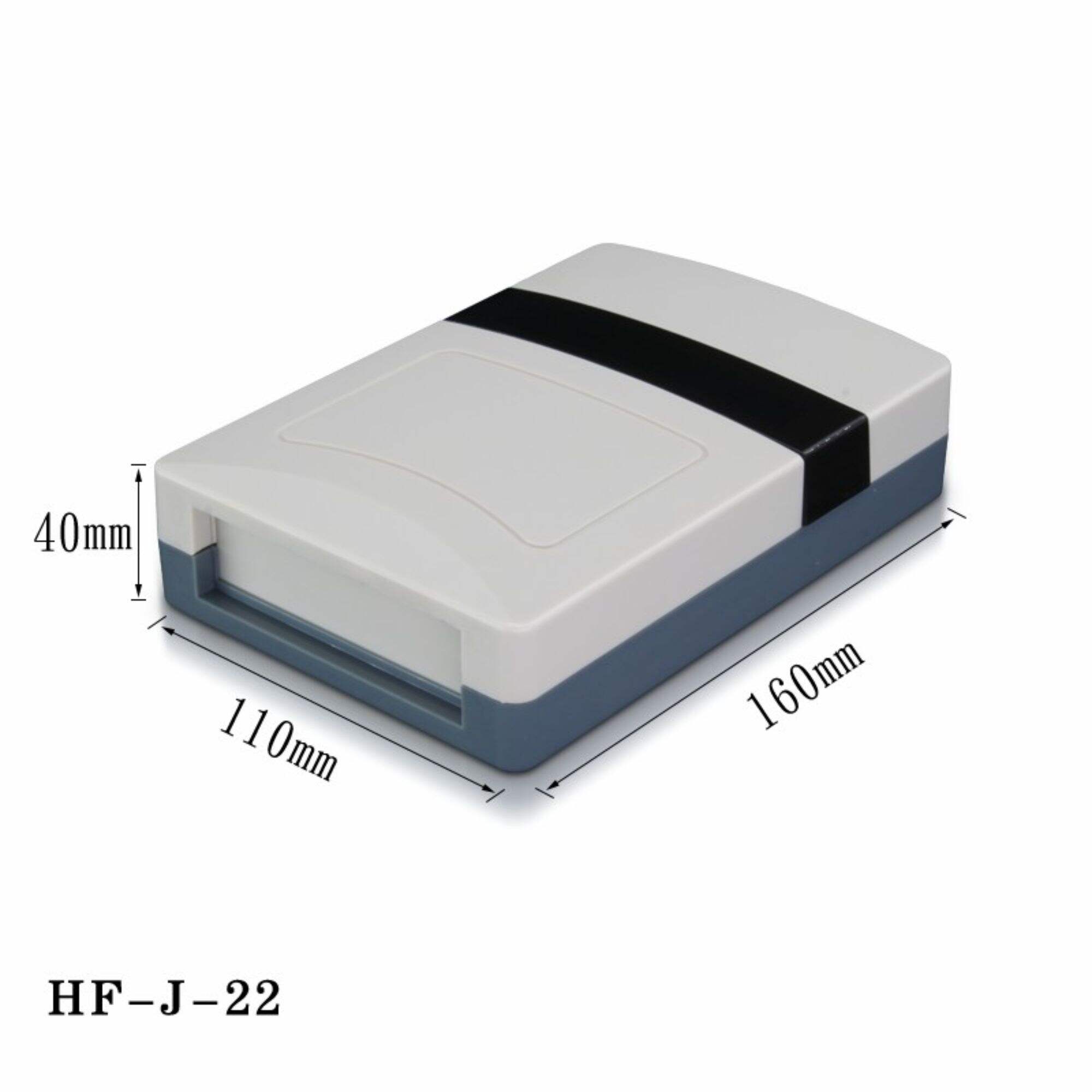

complete product line, ranging starting plastic boxes, aluminium enclosures, sheet metal housings CNC precision machined components, standard products custom-designed OEM products meet various requirements different customers. Our plastic metal cases ideal assortment industries uses include construction, electronics medical equipment, construction, many more. No matter you need tiny, durable case your USB large robust case protect power tools We have solution you.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy