EXPLORING ELECTRONICS: Realizing the Significance of PCB Housing Plastic Materials

Printed circuit boards (PCB) are the backbone of every device functionality that connect electronic components together. The protection hardware must be used to house them because they have died and can break easily if not properly supported. Hongfa Shunda aluminium pcb enclosure have been the preferred option by many manufacturers over the past years due to its several advantages.

PCB Enclosure Plastics: Ideal Materials for Electronics Manufacturing

A variety of PCB housing plastics are available for electronics industry manufacturers to select from based on their needs. ABS, Polycarbonate, HDPE and PPS are all materials most often used in manufacturing of followed by PET, Nylon, Peek, Acrylic, POM and PMMA. It has a strong overall performance or unique features such as high strength, dimensional accuracy, thermal processability and chemical resistance that provide different advantages for device manufacturers.

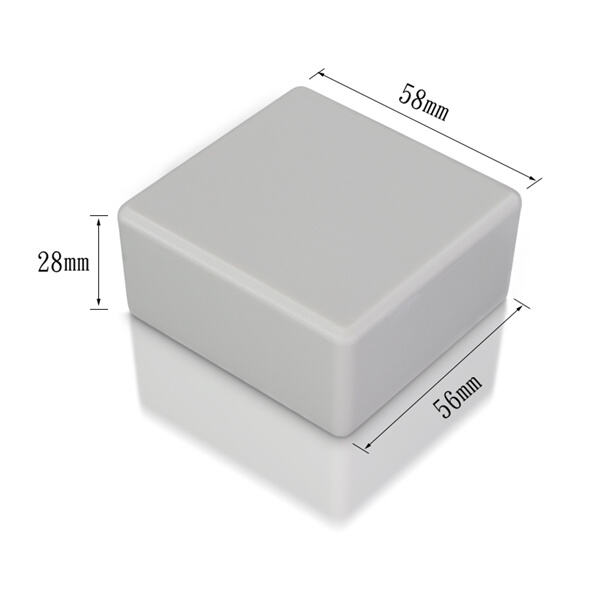

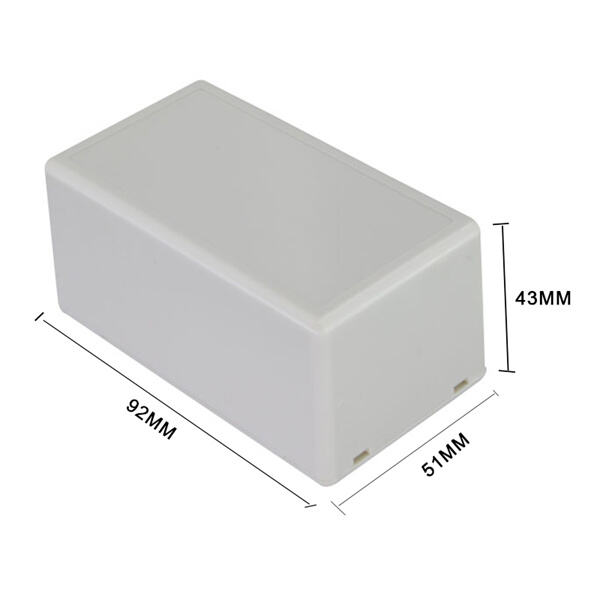

PCB housing plastic usage provides an array of benefits for the electronics companies. The material is super affordable and easy to produce. It also works best for portable devices like mobiles and tablet due to its light weight. Its high level of configurability enables manufacturers to develop custom housings for individual devices and needs. The uniform stock of Hongfa Shunda pcb enclosure box in multiple colors further increases device aesthetic quality and aids insulation to protect electronic components from electrostatic discharge. The material also features a chemical corrosion resistance that provides the ideal combination for operations in aggressive surroundings. It is recyclable which makes this a cost-efficient eco-friendly benefit that minimizes waste and conserves resource.

What to Consider When Choosing Printed Circuit Board Housing Plastic Materials

While selecting the right PCB housing plastic for electronic devices, manufacturers need to consider several important things. Durability is the dominant matter by which most plastics are judged-whether they are suitable for regular use or might succumb to such wear over time.

Significant progress in the area of PCB housing plastics has been made over recent years. Significantly, with the inception of biodegradable plastics provides a friendly approach as opposed to other materials. While biodegradable plastics that are derived from renewable resources can be compostable and decompose into natural substances in the environment. The production of nanocomposites delivering Hongfa Shunda pcb enclosure with superior mechanical performance, chemical resistance and thermal stability contrasts traditional materials. But new technology such as injection molding has fundamentally changed how electronic devices can be produced, making the manufacturing process for electronics more efficient and faster.

Plastic is still one of the most common materials that are used for PCB enclosures, but metal has also become popular in electronic applications too. The metal housing will help to protect the electronics from electro-magnetic interference, shock and temperature changes. But the density of metal limits its use in mobile devices, like smartphones or tablets. The pcb plastic enclosure also says the higher production costs of metal confine it from mass manufacturing and prevent its use in high-volume applications. Continued technological innovations to the properties of plastic have made such material increasingly desirable for a range of applications within electronics.

The benefits of a PCB housing plastic are various including lower costs, high strength, lightweight and very customizable. Manufacturers can choose a plastic material to address their custom needs in terms of durability, size or weight. The ongoing technological advancements are facilitating the manufacture of PCB housing plastics from biodegradable plastics, nanocomposites and via processes that have potential to fine tune properties further amid iterative cycles. All these benefits make aluminum enclosure box pcb a perfect material for electronics industry which is growing every day.

To meet requirements our clients, we offer full product lines, include aluminum, plastic plastic enclosures, housings made sheet metal. We offer CNC precision machined components Standard products including OEM and standard products, more. Plastic metal cases suitable numerous industries applications like construction, electronic equipment medical equipment more. We have solutions all your requirements, whether you looking robust, small case USB huge, tough case power tools.

We offer tailored solutions meet clients' specific requirements. work closely clients offer solutions beyond expectations, whether manufacturing prototyping. Our Pcb housing plastic range services allow to take complex projects beginning end.

Hongfa Shunda put quality first spot, Pcb housing plastic product, purchase raw materials, monitoring each process 100 visual inspection prior shipment packaging. We make highest level effort ensure item purchased customer qualified high quality.

team made up highly-skilled engineers, technicians craftsmen years experience knowledge Pcb housing plastic. pay attention every little detail ensure product exceeds highest quality high-precision standards

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy