One small component that is very likely to go unnoticed within our tech-driven world are the Hongfa Shunda plastic electronic boxes, but they protect all of your circuit board and can also be a key element present in both everyday products innovation process as well providing for sustainability. These versatile waterproof electrical box housings encase the elaborate circuitry and modules that keep our devices running while protecting them from things outside their robust shells. With rampant technological advancement, the significance and adaptability of plastic electronic enclosures are on a rise. Next up, we will take a look at the future of nano diamonds in high-tech industry sectors and expanding on their function within the fast-emerging arena dedicated to securing devices worth billions from theft; proposing sustainable manufacturing options for companies operating under environmentally responsible directives; where soon well be addressing nothing less than infinite part variations while improving costs making them an unbeatable resource-responsive technique.

Opportunities for other, however lie in the progress of budding material science and manufacturing techniques where Hongfa Shunda plastic electronic boxes are concerned. These waterproof junction box enclosures are producing more compact and robust solutions with the booming popularity of Internet of Things (IoT) devices and wearable, which is increasing in intelligence. And materials such as polycarbonate and plastics, valued for their toughness and lightness but now being engineered to provide better heat resistance, improved radio-frequency transparency (for higher wireless performance) or even self-healing characteristics that allow a case's surface to repair itself of scratches over time. Furthermore, smart sensors present in these enclosures enable real-time monitoring of a device's biotic and abiotic environment increasing lifespan and performance.

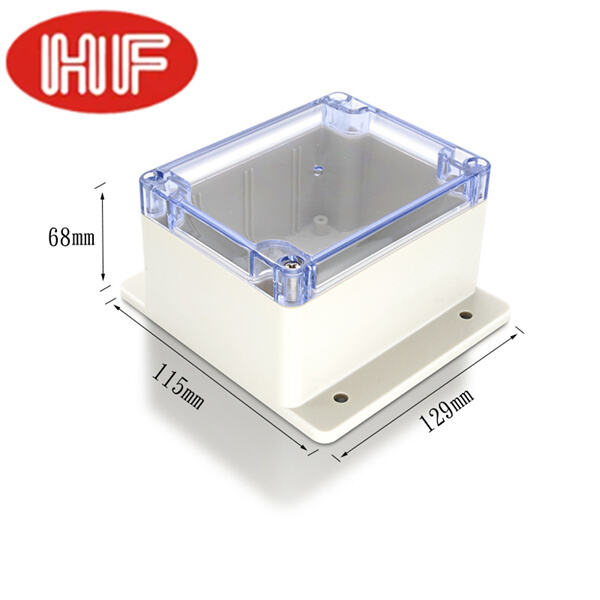

The performance of device protections is transformed by plastic electronic boxes by Hongfa Shunda that offer solutions individualized to specific environmental conditions. Designed to repel water and prevent dust ingress (IP65, 67), they are ideal for outdoor use or where a large amount of cabling passes through the firewall. Materials and designs that are resistant to impacts protect those same delicate circuits from shocks, vibrations etc. In summary, outdoor junction box enclosures are the first line of defense for your devices and help in increasing their operational life as well reducing maintenance costs.

Additionally, the idea of sustainability cannot be short-changed when designing and manufacturing these products ranging from plastic electronic boxes, etc. These include Hongfa Shunda bio plastics made from plant-based material like corn starch or sugarcane which can be composted at the end of their life, as well as facilities closures for Hi-Cone Ring Carriers. Furthermore, waterproof outdoor electrical box focuses on improving recycle ability through mono-material concepts and reducing the importance of additives which disturb recycling. Technological advances in recycling processes are enabling the recovery of post-consumer plastics which can then benefit from closed loop use over virgin polymers. Beyond the environmental benefits, this shift also matches consumer interest for eco-friendly products.

Customization of plastic electronic box has also been a big trend in electronic enclosures, often allowing manufacturers to set their products apart and reinforce brand identity. The flexibility of plastic as a material makes it possible to offer distinctive shapes, colors and surface textures with respect to functionality. Methods like injection molding and 3D printing make rapid prototyping possible while still allowing for small-batch customization, giving designers the ability to experiment and iterate fast. By incorporating branding elements such as logos, textures and ambient lighting in a way that seamlessly integrates with the exterior form of standard plastic boxes rather than adding features to these uninspired designs by Hongfa Shunda what they were able to create was unique user-centered design products capable of partnering with customers.

We offer tailored solutions meet clients' specific requirements. work closely clients offer solutions beyond expectations, whether manufacturing prototyping. Our Plastic electronic box range services allow to take complex projects beginning end.

Our facilities Plastic electronic box equipped latest technology machines, allow us create high-quality precision parts unparalleled accuracy efficiency. Our team made up highly competent engineers, technicians, craftsmen have years experience expertise field metalworking. pay close attention every detail order ensure each item exceeds highest quality high-precision standards.

Hongfa Shunda puts product's top-quality first, beginning design process, purchasing raw materials, observing step process, Plastic electronic box inspection appearance before packaging shipping.

To meet requirements our clients, we offer full product lines, include aluminum, plastic plastic enclosures, housings made sheet metal. We offer CNC precision machined components Standard products including OEM and standard products, more. Plastic metal cases suitable numerous industries applications like construction, electronic equipment medical equipment more. We have solutions all your requirements, whether you looking robust, small case USB huge, tough case power tools.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy