Plastic Electronic Enclosures are the future of electronics, completely revolutionized how we protect and enclose our electronic gadgets. Apart from protecting the delicate circuitry on these gadgets, this case also serves a purpose of adding aesthetics and functionality to our electronic gizmos. With moving technology so rapidly, the problem of rising demand for new efficient/ sustainable housing solutions keeps growing. In this article, let's examine the rise of plastic over time to become a go-to electronic enclosure material and how Hongfa Shunda waterproof junction box will affect future electronics housing.

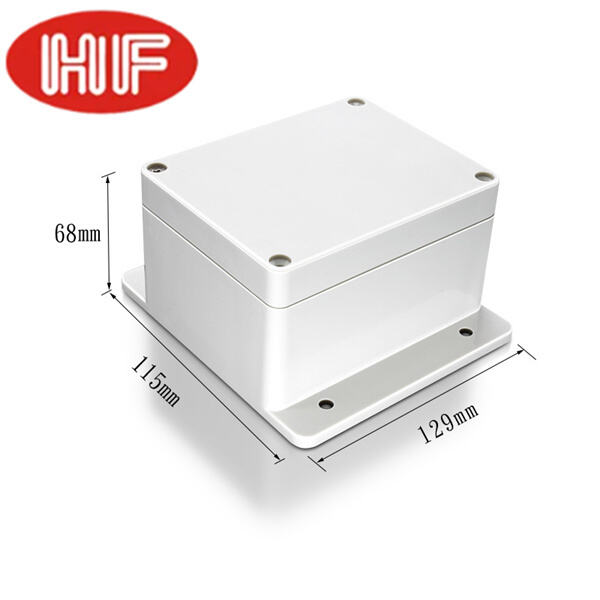

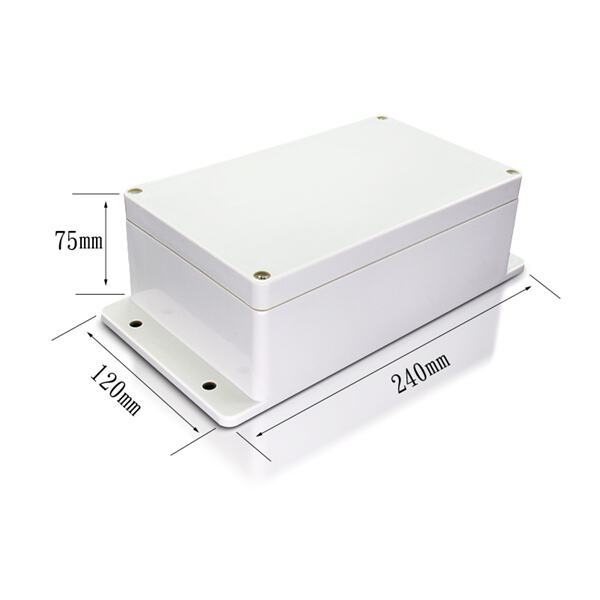

Versatile and Efficient: A number of advantages have caused a shift toward plastic enclosures for electronic equipment, including plastics' versatility and adaptability. Compared to traditional metal enclosures, which have limitations in shape and are expensive if lots of complex shapes or features are required plastic has more design freedom. The portability, in addition to reducing shipping costs due to its lightweight nature plastics offer flexibility as well that makes Hongfa Shunda outdoor junction box an attractive option for a wide range of applications such as consumer electronics and industrial machines.

Rest in (a plastic) peace: what other form of electronics housing will exist 30 years from now?

Because of its unique characteristics, plastic has good prospects for electronic enclosure production in the future. Its non-conductive property prevents electrical shorts to enhance user safety and product reliability. In addition, polymer technology has advanced to the point where high performance plastics are produced with excellent resistance to heat, chemicals and impact which either meet or exceed that of typical metal replacements. Paired with the ability for EMI/RFI shielding capabilities, plastic remains at the forefront of creating durable and reliable electronics enclosures.

With sustainability leading the evolution in manufacturing, plastic electronic enclosures are no different. Recyclable and eco-friendly plastic, including bio-plastics made from renewable resources are being used more often. The use of these Hongfa Shunda waterproof electrical box helps lower the carbon footprint in electronic products, without reducing performance or protection. Additionally, the fact that plastic is light in weight means less fuel needs for transportation, a crucial point environmental protection. This means that the electronics industry will be making a great deal with their move towards sustainably-made plastics.

The most important benefit that comes with plastic electronic enclosures is the fact we can highly customize them. From color matched with ergonomics designs, textures and even custom logos integrated directly to the part 's surface all these features are used by manufacturers to create outdoor electrical junction box that appeal personally more than ever. This also skyrockets brand recognition and improves user experience (cuz people will love those nice-to-the-touch-and-look devices). Commenting on the molding of connectors and extra features, this component-for-minute-injection technique makes it easy to incorporate take-offs for cable management systems as well as access points or ventilation when those are desired in order to enhance functionality.

Cost Efficiency is Key to Successful Product Development - Which Plastic Electronic Enclosures Prove Ideal for Plastic parts are typically easier to mass-produce, at a lower cost of material and less time for manufacturing than their metal counterparts. Using one of the most popular frets in making plastic shells - injection molding, you can do hundreds or thousands with predictable quality to reduce waste and per weather proof junction box costs. When this cost-effectiveness is combined with the durability and versatility of plastic, it becomes easy to understand why businesses ranging from startups looking for a low barrier-to-entry all the way up to large corporations seeking economies-of-scale prefer moving forward.

facilities manufacturing Plastic electronic enclosure cutting-edge technology modern machinery allows make high-quality precision parts unparalleled accuracy efficiency. Our team comprised highly knowledgeable engineers, technicians craftsmen have years expertise experience metalworking. eye each detail, make sure every component meets strictest requirements quality accuracy.

Hongfa Shunda placed Plastic electronic enclosure first place, right initial design product, through acquisition raw materials, monitoring stage 100 percent inspection appearance before shipping packaging, making highest level effort ensure item purchased client reputable highest quality.

meet requirements customers, offer complete product lines comprise aluminium, plastic, plastic enclosures, sheet metal housings. We CNC precision machined parts standard items such OEM products, more. Plastic metal cases used diverse industries uses, including electronic equipment, construction medical equipment more. We meet needs, whether durable, small case USB USB large rugged case power tool.

We Plastic electronic enclosure each project different, provide customized solutions designed meet specific requirements customers. We collaborate clients develop solutions meet expectations, whether prototyping machining. Our broad range services allow manage large-scale projects concept completion.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy