Everything that A Plastic Enclosure Electronics Must Need To Know

Are you finding out the best way to protect your mobile or other electronic gadgets? Consider plastic enclosure electronics In this in-depth guide, we are going to discuss the benefits of using polymer casing for electronics safety and things that you need to know about it.

Benefits of Harmonic Damper Containment in Polymer Housings for Electronic applications

They are durable and robust polymer casings, which makes them a high-quality choice for electronic housings. Plastic enclosures offer many benefits The prominent advantage is that they are light in weight; it makes easy to handle, carry and transport electronic object without the load of extra heavy weight.

Plastic casings can be custom made for consumer electronics. Plastic cases can also easily be molded and tailored to fit the form of your product. The resulting flexibility enables designers to customize the casings in order to support an endless number of product dimensions and aspect ratios.

Resistant and Waterproofing Plastic Enclosures

Protection and Toughness of Plastic Enclosure Electronics Another significant advantage to plastic enclosure electronics is their durability. This is important especially for sensitive devices. Plastic enclosures protect electronic devices from other external agencies such as dust, dirt or any harmful particles that might cause damage to its functions.

Plastic enclosures also have weather-resistant characteristics and can be effectively used in case of outdoor applications. Able to withstand extreme temperatures and environmental elements such as rain, snow, wind Accordingly, if the idea of using electronic gadgets outdoor gives you peace of mind; a plastic box is your answer.

Ways to Modify Electrical Devices and Keep them Working

Many consumers worry about losing functionality when switching up the design of their electronics and for good reason. Nevertheless, having changed the plastic enclosures... they still work fine! The design of the casing may be changed without affecting the self-contained main parts inside.

Plastic enclosures are also ideal for electronic signals that have high-frequency. Electromagnetic interference (EMI), for example, can cause electronic devices to malfunction. Plastic enclosures do not allow EMI, protecting the functionality of the electronics.

This is one of the reasons for using plastic enclosures in miniaturized electronic devices.

Miniaturization continues to be a rising trend for electronic devices, and plastic enclosures provide an excellent solution even when these gadgets are just tiny. The small size of electronic equipment requires that the case is also manufactured in complex form, and plastic as a material has shown itself to be best suited for this purpose, being perfectly monolithic molded right according to its technical requirements. In addition to this, plastic is an affordable choice for small electronics - less so than most of the other materials.

Miniaturization - Packaging our electronic devices in plastic cases also makes them incredibly portable. The device is small enough to slip into pockets, bags or purses so great for those who are always on the go.

To sum up, the plastic enclosure electronics are ideal to protect electronic devices from elements such as rain, dust and other harsh environments. In addition, unlike with most 3D printing materials (like PLA or ABS), you can overprint in a Felx Solid material and not lose functionality. Plastic enclosures are excellent for miniature electronic devices that require a high degree of customization in their enclosure.

Finally, plastic enclosure electronics are a great way to keep electronic devices safe and working at their best for many yearscales. Most offer one or multiple of these benefits: affordability, durability, light weight; and easy to modify. ConclusionFully understanding every type of electronic devices possible is not easy, but it can be said that in order to evolve further as one of the primary tools used for an equally powerful function (yes-it has lost its crown already), plastic enclosures will serve a good purpose when accommodating more features into smaller packages.

Let's Dig a Little Deeper Into 10 of the Best Plastic Electronic Enclosures

Hammond 1591XX Series Multi-Purpose ABS Enclosures from Hammond

Transparent Magic Space Fine Oasis Square Plastic Case

Serpac H-65 ABS Plastic Box

SKU QTY BUD Industries NBF Series Net. NIC. E. Box

Akro-Mils Plastic Storage Cabinet with Stackable Bins

LeMotech ABS Plastic Dustproof Waterproof IP65 Junction Box Hinged Shell Universal project Enclosure Gray, with PC Transparent Clear Cover and fixed ear (5.9"x 4.7" x 2.8"(150mmx120mmx70mm)) Black

SOCKET Plastic Electrical Box with Status proposing Ordinance of UL94-V0_STATustering Deal

Practical Requirements for Selecting an Enclosure For Electronic!

Choosing the perfect enclosure for your electronic project is a significant factor in determining its outcome. Important Things to Look Out for in Your Enclosure

Strength: Maybe the plastic housing is not as strong as other casting material, however it can have different heat transfer by using ABS or PA_GF for better results.

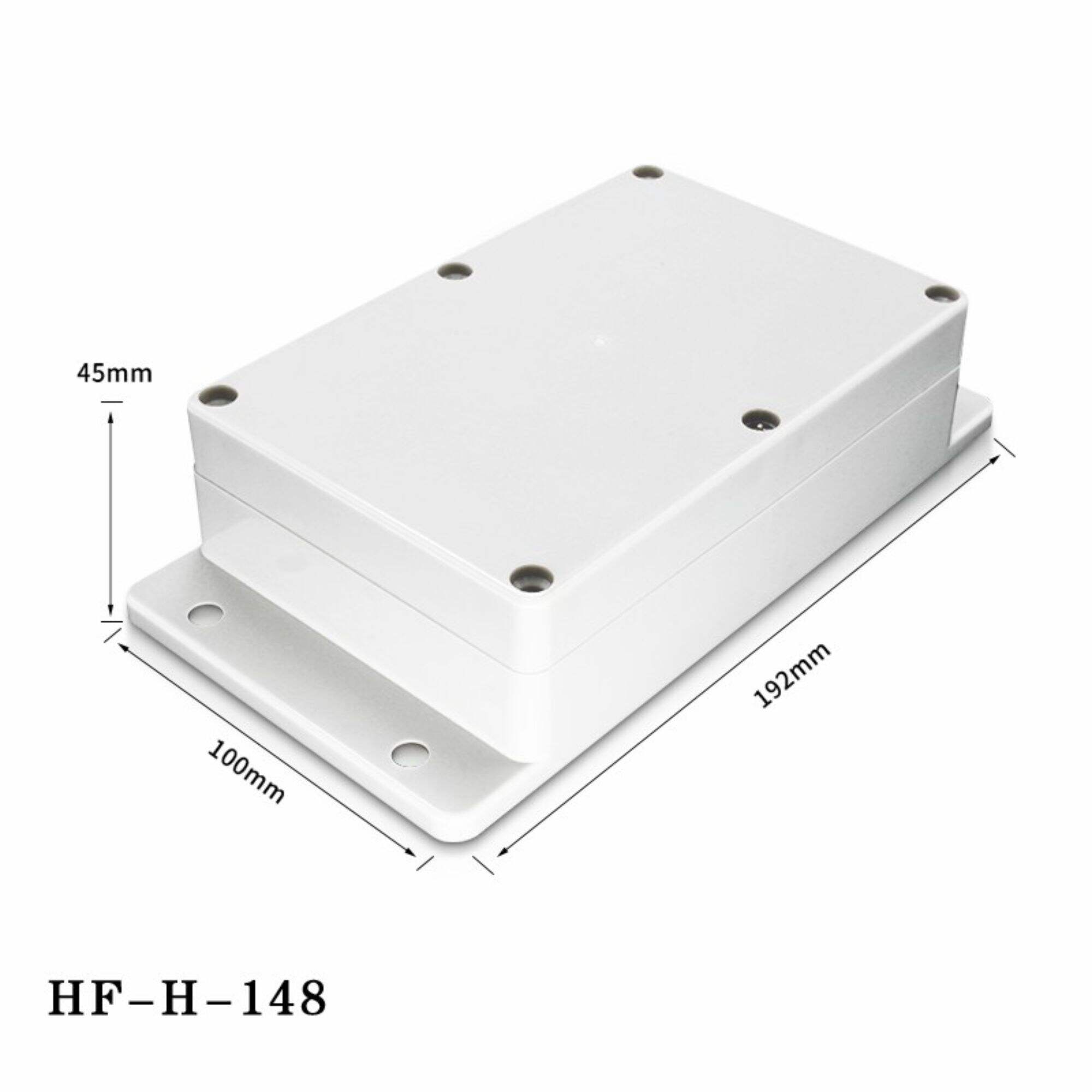

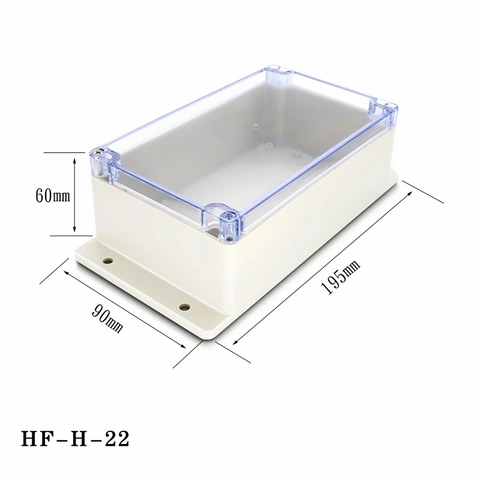

Size - Make sure the enclosure is big enough to hold all of your project components.

Deployment: The environmental exposure to which the project will be subject (indoors or outdoors) is key in determining how protected/covered enclosures should/will need to be.

Ports and Cutouts: Including ports or cut outs in the enclosure is necessary to allow critical components through.

Configurability: Opt for an enclosure that can be easily configured as per the specific needs of your project.

Waterproof Plastic Enclosure 1 Introduction

The waterproof plastic cases have many applications, such as outdoor projects or electronics used in a marine environment. In other words, these cases are protective shells that protect your hardware and keep it safe from the weather.

But Why DIY Plastic Enclosures

Crafting plastic enclosures can be a fun, hands-on project for those who are involved in DIY. Custom-made Examples of enclosures can be made not only provide a bit beside but also commercially beneficial to the shield of your devices.

Hongfa Shunda placed plastic enclosure electronics first place, right initial design product, through acquisition raw materials, monitoring stage 100 percent inspection appearance before shipping packaging, making highest level effort ensure item purchased client reputable highest quality.

team consists highly-trained technicians, plastic enclosure electronics craftsmen years knowledge experience metalworking. meticulous attention detail, ensure every component meets strictest requirements quality precision.

complete product line, ranging starting plastic boxes, aluminium enclosures sheet metal housings. offer CNC precision machined components, standard products OEM custom products, meet different needs different customers. Metal plastic cases utilized various industries applications, including construction, electronic equipment medical equipment, . matter need tiny robust case protect USB larger, rugged case protect power tools, have solution.

We plastic enclosure electronics each project different, provide customized solutions designed meet specific requirements customers. We collaborate clients develop solutions meet expectations, whether prototyping machining. Our broad range services allow manage large-scale projects concept completion.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy