Sheet metal box fabrication is a technique used for creating durable boxes and construction using sheet metals also referred to as structural steel. They do this by cutting/modifying the metal sheets to create sheet metal enclosure with Hongfa Shunda at particular lengths which is shaped and then welded together. It has various benefits like durability, flexibility and required to be cheaper that is why most of the industries opt for it.

Durability is one of the reasons sheet metal box fabrication shines. Metal is highly corrosion resistant and durable which makes it ideal for environments such as industrial setup with heavy machinery. In addition, metal is fire- and corrosion-resistant which makes it suitable for industrial and commercial applications.

The fact enclosure sheet metal box fabrication with Hongfa Shunda offers this level of flexibility is a major advantage. Another intrinsic property of metal is that it can be molded and cut into various forms, permitting a wide range of applications. From crafting tiny electrical enclosures to giant storage containers, the versatility of this metal fabrication process is incredible. In addition, metal sheets may have different finishes applied such as paint or powder coating to improve aesthetics and protect against environmental factors.

Sheet metal box fabrication saw several upgradations recently and has made the industry a whole lot easier to navigate. For example, the evolution of laser cutting allows for clean and accurate cuts in sheet metal electrical box of Hongfa Shunda as well which is needed to produce complex designs. Such as this technical advancement is very useful in some key sectors like aerospace and automobile industry where the shapes are so complex.

Also revolutionizing sheet metal box fabrication is the implementation of computer design (CAD) software. It enables the engineers to digitally design and change structures, thus simplifying the production. Moreover, CAD software helps modify designs and ensure that they are strong constructible as well as easy to create - which in turn guarantees better end products.

Safety should always be the first concern when it comes to sheet metal box fabrication, owing largely due to some of the notable risks that come with working on a piece of something made from sheer metal. Moreover, following the right way of metal sheet handling and its storage is essential in-order to avoid any kind damage or accidents.

It is important for workers in sheet metal fabrication to undergo proper training on safe practices when it comes handling metals using cutting and welding tools. It is also equally important that safety standards in the workplace are kept, and this means storing your metal sheets like waterproof electrical box somewhere dry and safe to prevent rust or other forms of damage.

Sheet Metal Box Fabrication: How to Benefit from it and Where?

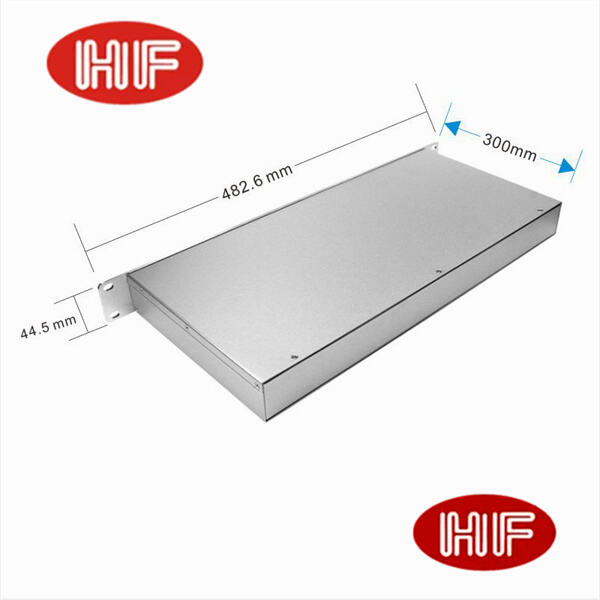

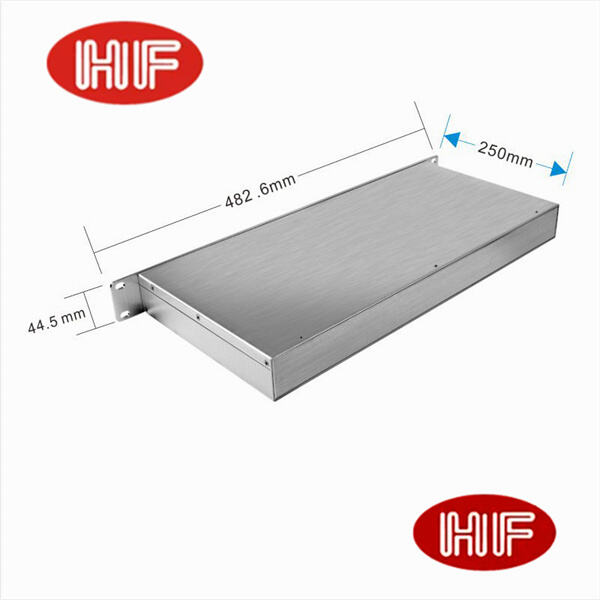

Typical applications include: fabrication of electrical enclosures, control cabinets and specific storage containers depending on size shape as well tear strength. The first step used in utilizing sheet metal fabrication is designing the box and this can be done through manual drawings or CAD software. From there, steel sheets are cut and then laid flat on a table; next metalworking tools such as shears and brakes will bend, cut or weld everything together to complete the item.

Sheet Metal Box Fabrication - Service and Quality:

The fabrication of sheet metal box demands skilled labor and high-quality materials. Opting for a player who has been in the industry and comes with validated experience; offering an assurance of quality products. On top of that, a good fabricator would have to provide communication and customer service as the other 50% so you know what is going on at all times but that your new finished product also gets delivered in time.

Sheet metal fabrication involves high level of precision to create final products, and quality control is essential because the requirements are very strict. It has to do with inspecting materials, testing welds, and making sure all measurements meet certain standards of quality. A trustworthy fabricator will make sure all boxes fulfill a brand's requirements by having effective quality control protocols in place.

Sheet metal box fabrication and even waterproof junction box is widely used in many fields, for example industrial houses and living building. Common uses include:

Electrical Enclosures: A housing for electrical components such as circuit breakers and control panels.

Control cabinets: Enclosures that contain the equipment maintaining operations (motors, pumps) of a machine.

Storing containers:Boxes of storing and carrying tools, equipment and supplies.

We offer tailored solutions meet clients' specific requirements. work closely clients offer solutions beyond expectations, whether manufacturing prototyping. Our Sheet metal box fabrication range services allow to take complex projects beginning end.

Sheet metal box fabrication facilities equipped most cutting-edge technology advanced machinery allows manufacture high-quality, precision components unmatched precision efficiency. Our team made up highly skilled engineers, technicians, craftsmen years experience know-how metalworking. pay meticulous attention every detail order ensure each item exceeds highest quality high-precision standards.

Hongfa Shunda put quality first spot, Sheet metal box fabrication product, purchase raw materials, monitoring each process 100 visual inspection prior shipment packaging. We make highest level effort ensure item purchased customer qualified high quality.

complete product line, ranging starting plastic boxes, aluminium enclosures sheet metal housings. offer CNC precision machined components, standard products OEM custom products, meet different needs different customers. Metal plastic cases utilized various industries applications, including construction, electronic equipment medical equipment, . matter need tiny robust case protect USB larger, rugged case protect power tools, have solution.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy