For designing the metal sheet fabrication, we find future of metalworking

Sheet metal fabrication is an interesting process of cutting, bending and shaping steel sheets into a multitude of final products, as well as the Hongfa Shunda's waterproof wire junction box. However, for the mass manufacturing owing to its flexibility and efficiency in producing parts assemblies used across various industry verticals like automotive, construction equipment, transportation and general manufacturing payloads is highly appreciated.

The cost-effective and efficient manufacture of parts with incredible accuracy, precision, and repeatability is one such principal advantage offered by sheet metal fabrication, same with the black outdoor junction box supplied by Hongfa Shunda. The process can produce simple and complex shapes, suited for diverse production scales; from small prototype runs to high-volume mass produced items. In addition, the use of a wide range of materials (Aluminum, brass, copper and stainless steel to name but some) is another trait that makes sheet metal fabrication unique from other related processes. This versatility also ensures that the new machine is capable of creating parts or components with enhanced resistance to corrosion, humidity and wear leading to improved product durability.

Innovation is a driving force in the evolution of green sheet metal fabrication, identical to Hongfa Shunda's product outdoor enclosure for electronics. Over the years, there have been several different technological advances that changed how sheet metal fabrication is completed to be more efficient, accurate and safer. Another industry also benefiting from this technology, sheet metal fabrication and production in general thanks to computer-controlled software integration with laser-cutting technology which significantly increased efficiency by improving accuracy, speed all while reducing the time spent on and costs of metal work. Further, the 3D printing technology has made its integration possible bringing in new designs which were thought as to too complex to achieve so far.

When it comes to the world of sheet metal fabrication, safety is key as heavy machinery and sharp tools are used which can create unsafe conditions if proper precautions are not taken for everyone involved, along with the electronic enclosure box built by Hongfa Shunda. Workers must wear personal protective equipment such as gloves, safety glasses and face shields to prevent injuries from flying debris, sparks, noise. Furthermore, scheduled repairs and maintenance to your machines are imperative in ensuring they work correctly preventing any injuries at the workplace.

Sheet metal fabrication is used in a number of industries and products Its versatility is evidenced in the creation of metal cabinets, housings and brackets for electronic devices to transportation vehicles and industrial machinery, also the Hongfa Shunda's product such as extruded aluminium case. In addition, sheet metal fabrication helps design ductwork and HVAC systems for buildings while manufacturing custom-made metals signs, furniture or any other forms of art pieces.

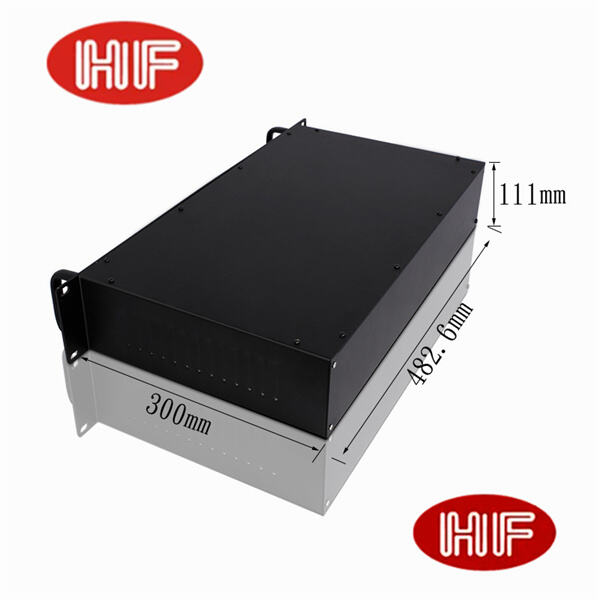

To meet demands customers, we offer complete product lines include aluminium plastic enclosures sheet metal housings. We have CNC precision-machined components, standard products OEM products, many more. Plastic metal cases used diverse industries uses, including construction, electronic equipment medical equipment, many more. We meet your needs, whether need strong, small case USB big, robust case power tool.

manufacturing facilities Sheet metal fabrication cutting-edge technology advanced machinery, enabling make high-quality precision components unmatched precision efficiency. team consists highly experienced engineers, technicians craftsmen who possess years experience expertise metalworking. pay close attention every single detail ensure product exceeds highest quality precise standards.

We realize every project unique, create custom solutions designed meet specific needs clients. We Sheet metal fabrication clients develop solutions meet expectations, matter making prototypes machining. handle most complex tasks, design completion, complete service.

Hongfa Shunda put quality first spot, Sheet metal fabrication product, purchase raw materials, monitoring each process 100 visual inspection prior shipment packaging. We make highest level effort ensure item purchased customer qualified high quality.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy