Plastic Injection Moulding: A Fun Way to Make New Items We use it to make toys, cups, and even make car parts. Things don’t always work out exactly how you expect. That’s at the moment we need to know what went wrong and how to correct it. Hongfa Shunda will share with you some of the common problems in injection molding and some solutions to improve the products.

Detecting and eliminating sink marks in injection molded products

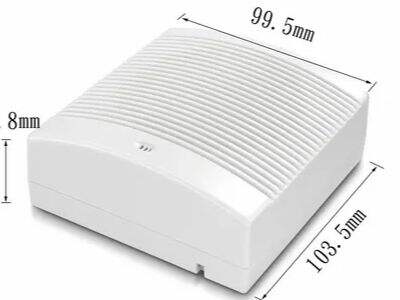

We may also observe small depressions in the surface if we sometimes create a plastic part. These waterproof electrical box are called sink marks. Sink marks occur when the plastic cools too quickly, causing it to shrink unevenly. We can also make the mold differently to address sink marks. We can place more vents to allow air to release, or we can alter the temperature of the plastic. It can be used for fixing sink marks, so the plastic items we create end up looking nice and smooth.

Good mold design will help to prevent warp and distortion

And Tests: What Is the Weirdest Fragment of Plastic You Have Ever Seen? It’s called warping and distortion. Waterproof junction box occurs as a result of uneven cooling or because the mold itself is not a good one." If the plastic cools unevenly, we can have either warping or distortion. We can accomplish this by creating cooling channels in the mold or temperature controlling the plastic. If we design for it, we can make our plastic things stay straight and flat.

Removing flash and burrs for a better surface finish

When we make a plastic item, sometimes we see extra pieces of plastic sticking out. They are termed flash and burrs. Flash outdoor junction box occurs when the mold is not tightly shut, and burrs occur when the mold is not smooth. So, to get rid of these seeds, check if the mold is closed properly and it is smooth. If we have flash or burrs we can trim them off or sand them. Flash and burr removal is used for clean finishing of plastic articles.

The process of identifying and rectifying air traps and voids in the molding

Small air traps, or voids, trapped in the plastic, like little bubbles. They occur when the plastic does not flow smoothly into the mold or when there is excess air trapped inside. Routing the cooling line through the mold design can minimize air traps and voids. We can have additional gates for plastic to flow through, or we can fine-tune the pressure of plastic,” Knowing about air traps and voids and how to correct them can help us in making strong and durable plastic parts.

Finding key problems and putting more focus on fixing them.

It’s like being a detective to find problems. We need to figure out what happened to our plastics and how we can do better with them. We can make mistakes, learn from them, and get better by seeking problems. We just need to fix things up a bit and we can make some quality fucking plastic and make even more of it. We can create better products together with Hongfa Shunda by correcting our failures.

Table of Contents

- Detecting and eliminating sink marks in injection molded products

- Good mold design will help to prevent warp and distortion

- Removing flash and burrs for a better surface finish

- The process of identifying and rectifying air traps and voids in the molding

- Finding key problems and putting more focus on fixing them.