So when you’re assembling aluminum sheet metal, there’s two ways to weld them. Each works its own magic on the metal, influencing how strong and durable the end product will be. Below in this article, is a comparison between the numerous welding Aluminum sheet metal techniques and their advantages.

Various Ways to Weld Aluminum Sheet Metal

A common method for welding aluminum sheet is called TIG welding. It uses a proprietary tungsten electrode which results in a precise and intense weld. Another is MIG welding, which involves a wire feed to weld the metal pieces together. For thin aluminium sheet metal parts, spot welding is also in place due to its fast, effective welding. Understanding these various approaches lets manufacturers choose which one will be best for them.

Influence of Welding in the Forming of Parts on Thin Aluminum Sheets

Aluminum sheet metal parts can be altered in many different welding processes, both for better and for the worse. On the plus side, the welding operation makes the metal stronger by creating a solid joint between the joining members. On the negative side, welding can sometimes make the metal twist or bend (a look, feel and affect on use). By studying how welding influences aluminum Sheet Metal, manufacturers are able to turn the volume down on issues and ensure the finished product comes out well.

Strength and Durability of Welding Processes Compared

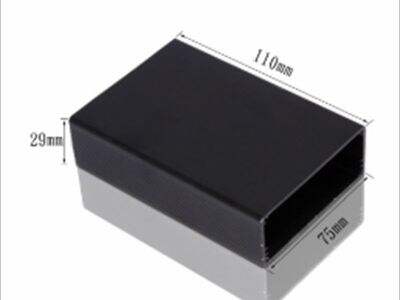

Various methods of welding can produce varying degrees of strength and longevity in the aluminum Sheet Metal Enclosure. For instance, TIG welding is a process that produces strong and accurate welds, which is also an advantage for heavy tasks. MIG is quicker and cheaper, but it may not be as strong as TIG. Manufacturers can then decide which method is best for their project by comparing the strength and toughness provided by these buoyancy methods.

Merits of Welding Aluminum Sheet Metal Parts

TYPES OF WELDING MACHINES and PROCESSES For Welding Aluminum Sheet Metal Parts

There are many advantages to welding aluminium sheet metal enclosure parts. 10 It makes a super strong connection between the metal components and it is cool because you can be more creative and have more variety of shapes. In addition, welding can be a relatively cost-effective means of fusing parts together, compared with using other joining techniques, which is why it’s used by so many manufacturers. Understanding the advantages of welding enables manufacturers to make intelligent decisions about how to construct their products.

How to Weld Aluminum Sheet Metal

WHAT ARE SOME COMMON APPLICATIONS FOR ALUMINUM SHEET METAL?

When it comes to welding aluminum sheet metal, here are some crucial tips for the best results. One, clean the metal surfaces you will be welding to eliminate any dirt or contaminants. Then modify the welding settings to ensure a strong and even weld. Last, please ensure you use some filler material to improve the strength of the weld and make it look nicer. Manufacturers can enjoy success when welding aluminum sheet metal parts by paying attention to the following.