Special cases to protect electronics and keep them safe include extruded enclosures. The enclosures are manufactured through a process called extrusion which produces strong and durable cases able to withstand the rigors of daily usage. In this article, let’s learn about the advantages of using extruded enclosures for electronics, how they are produced, applications and some tips for choosing the right one for your project.

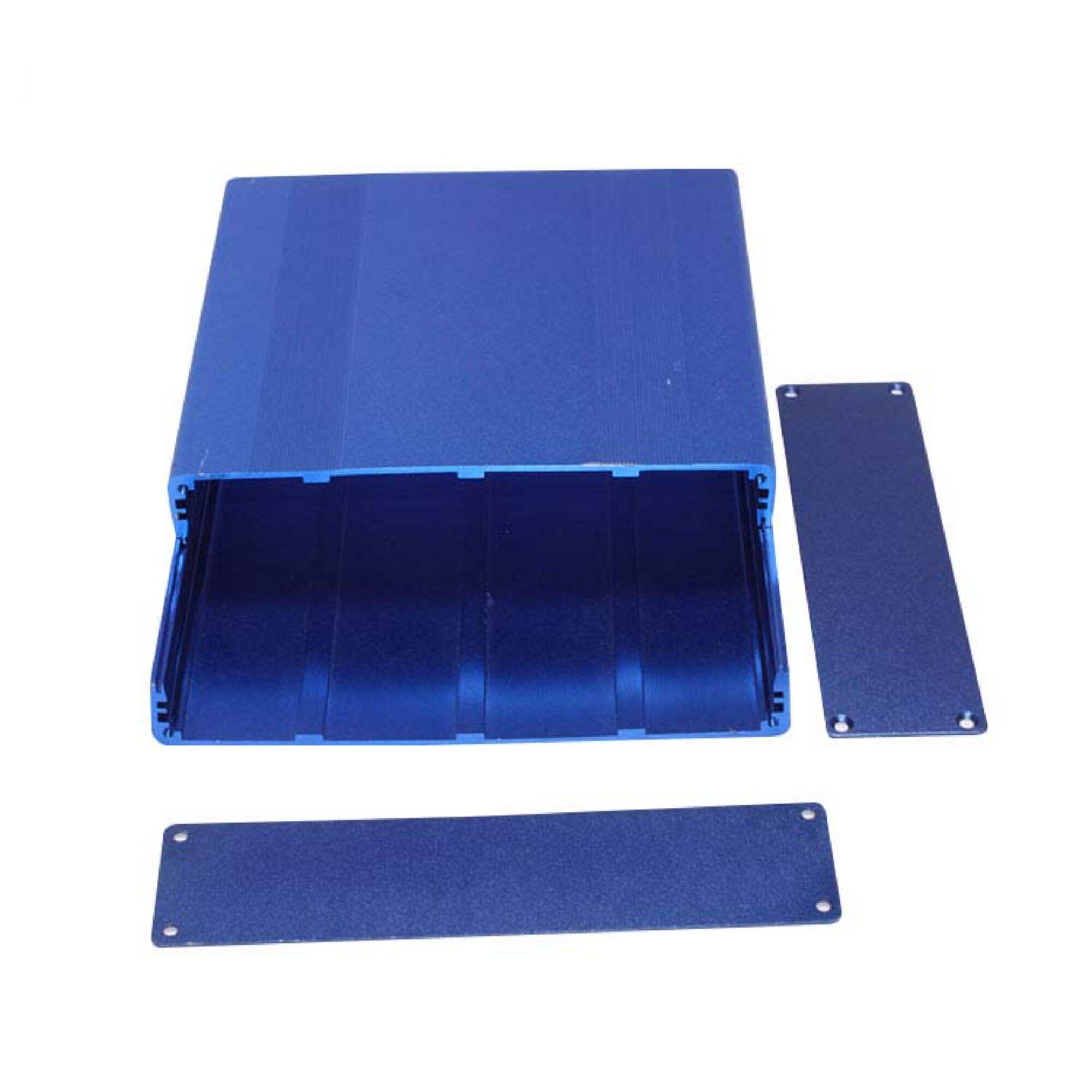

Extruded enclosures are an excellent option for protecting electronics: they’re lightweight, they’re strong and they’re not too costly. They are typically constructed of materials, such as aluminum or plastic, that are relatively easy to work with and can be remodeled to a particular end. These cases offer a variety of sizes and shapes to make them useful for numerous electronic items.

There are a few reasons to consider extruded electronic enclosures. One major reason is that they’re really strong. Extruded enclosures help protect electronic parts from the knocks, water, dust and other maladies that it might encounter. They are also lightweight, therefore easy to transport and install. And they are inexpensive, which works well for companies that want to secure their electronics without shelling out a ton of money.

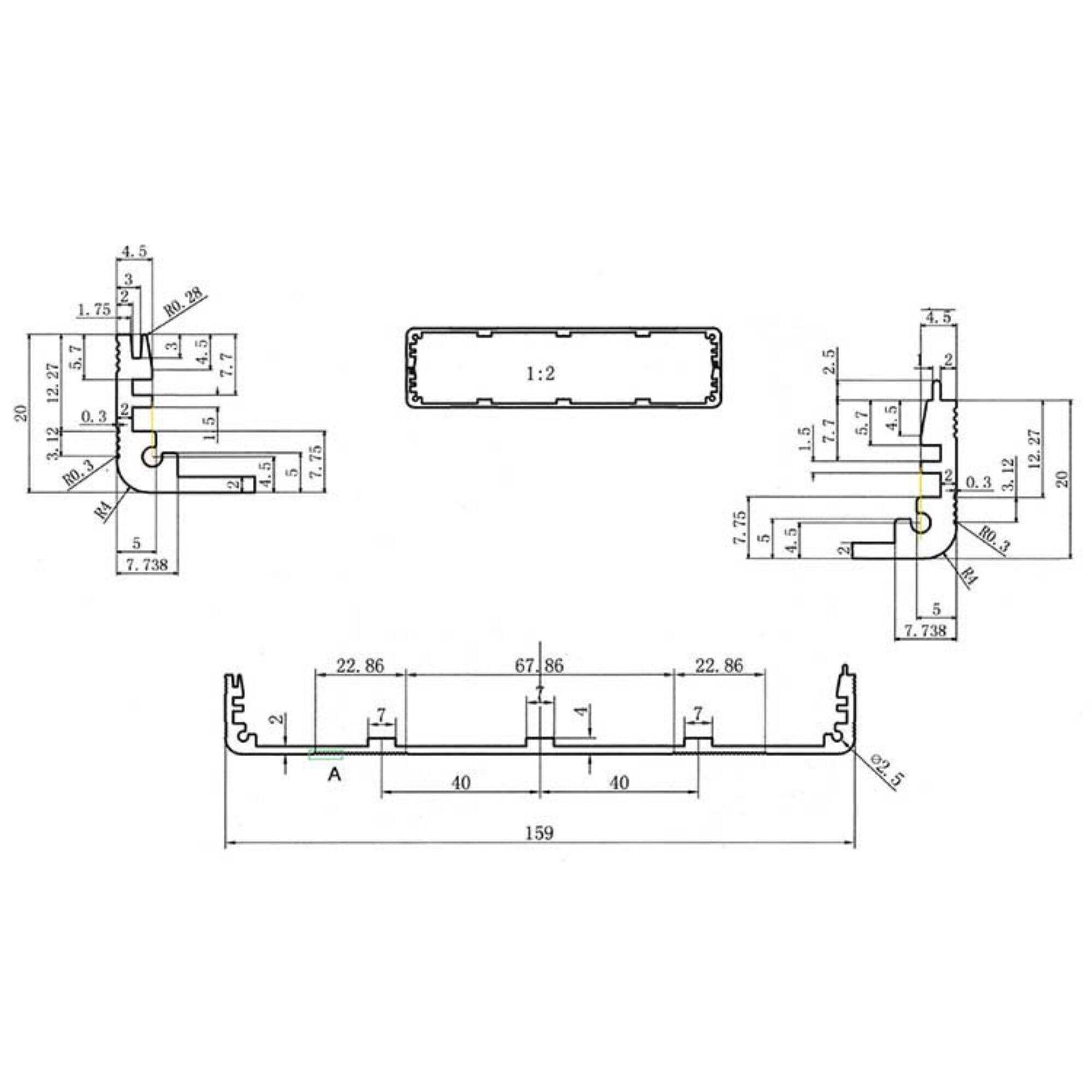

Enclosures that are extruded are produced via a process of extrusion. That is feeding a material through a shape so as to generate a particular design. This is slow enough where the individual can fine-tune precisely to their heart’s content and gets what the customer wants. Once the enclosure is formed, it can be customized with such elements as holes for buttons and screens, and finishes such as powder coating or anodizing.

Extruded enclosures can be found in a variety of locations from factories to homes. You’ve seen them in control panels, power supplies, medical devices and telecommunications equipment. The fact that they lend themselves to utilize in various applications has made them very popular in many applications.

When selecting an extruded enclosure for your latest project, consider a few considerations. First off, take into account the size and shape of the case: see if it will be fit for your electronics nicely. You’ll also want to consider what kind of material is the enclosure is made from, as they each provide a unique variety of protection. Finally, factor in any special features you might require, such as waterproofing or EMI shielding.

We realize every project unique, create custom solutions designed meet specific needs clients. We extruded enclosure clients develop solutions meet expectations, matter making prototypes machining. handle most complex tasks, design completion, complete service.

complete product line, ranging starting plastic boxes, aluminium enclosures, sheet metal housings CNC precision machined components, standard products custom-designed OEM products meet various requirements different customers. Our plastic metal cases ideal assortment industries uses include construction, electronics medical equipment, construction, many more. No matter you need tiny, durable case your USB large robust case protect power tools We have solution you.

Hongfa Shunda put quality first every extruded enclosure, starting conception product, acquisition raw materials, monitoring process along 100% appearance inspection before shipment packaging, making highest effort make sure item purchased client reputable high quality.

facilities manufacturing extruded enclosure cutting-edge technology modern machinery allows make high-quality precision parts unparalleled accuracy efficiency. Our team comprised highly knowledgeable engineers, technicians craftsmen have years expertise experience metalworking. eye each detail, make sure every component meets strictest requirements quality accuracy.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy