For electronic products, plastic housing can come in really handy. These gadgets need some protection from all of the bumps and scratches, and plastic covers do the job. Here is how plastic housing is revolutionizing the way things are being made.

Plastic casing in electronic products has several good benefits. Plastic is lightweight and sturdy so it doesn't bog down your devices. It can also be molded into any size and shape, so designing housing that fits snugly around all the important bits inside is a breeze.

Plastic housing is revolutionizing how things are manufactured at factories. In the past, housing for electronic devices had to be of metal or other weighty material. But now, with housing made out of plastic, manufacturers are able to create devices that weigh a little bit less and are more user-friendly. This is a cost savings on materials as well as the fact that many devices can be made at the same time.

Plastic housing may look fragile, but be in no doubt that it is extremely rugged! It can withstand drops and hits without breaking, an essential quality for protecting electronic devices. Plastic also comes in many colors and shapes, so manufacturers can be creative in how their devices look. This spontaneity allows them to design in a way that’s unique and eye-catching.

Plastic is strong! And useful! But also we have to care about the environment. Certain plastics can take hundreds of years to decompose, which can be harmful to the environment. That is why companies like Hongfa Shunda are experimenting with more viable alternatives to plastic housing. These modern materials can biodegrade — or are sourced from recycled plastics — making this a much better thing to do for our planet.

plastic housing provide customized solutions satisfy customers' individual requirements. We work customers deliver solutions exceed expectations, manufacturing prototyping. handle most complex projects beginning completion, through comprehensive services.

Our team made up highly-skilled engineers, technicians craftsmen years knowledge experience field of metalworking. plastic housing close attention every single detail ensure every product highest standard quality precise standards.

Hongfa Shunda placed plastic housing first place, right initial design product, through acquisition raw materials, monitoring stage 100 percent inspection appearance before shipping packaging, making highest level effort ensure item purchased client reputable highest quality.

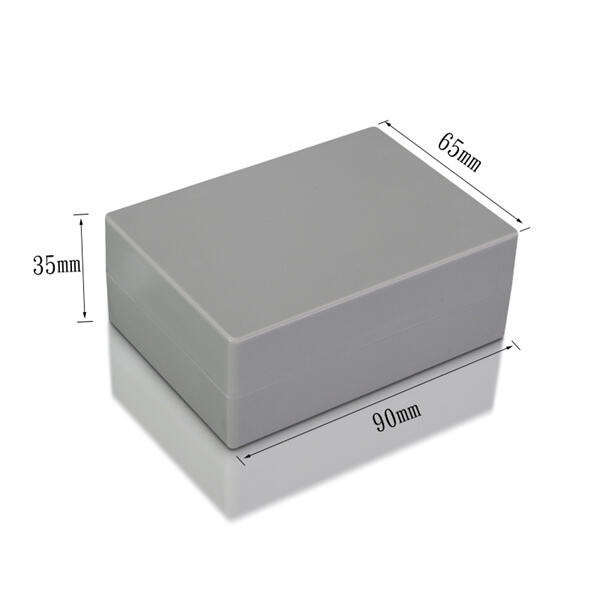

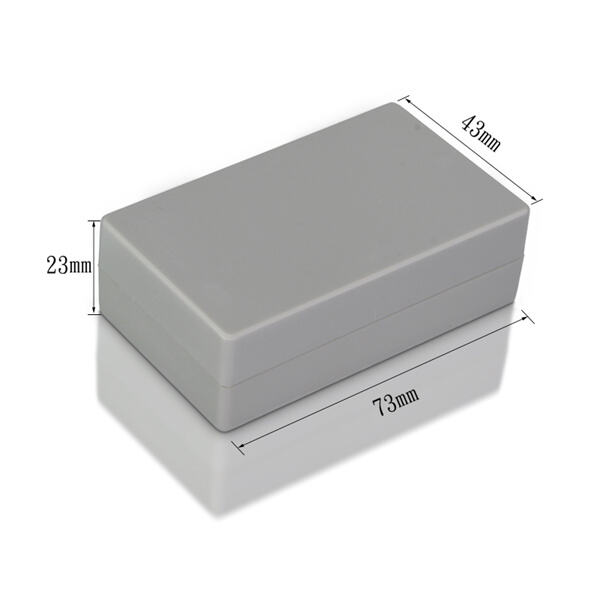

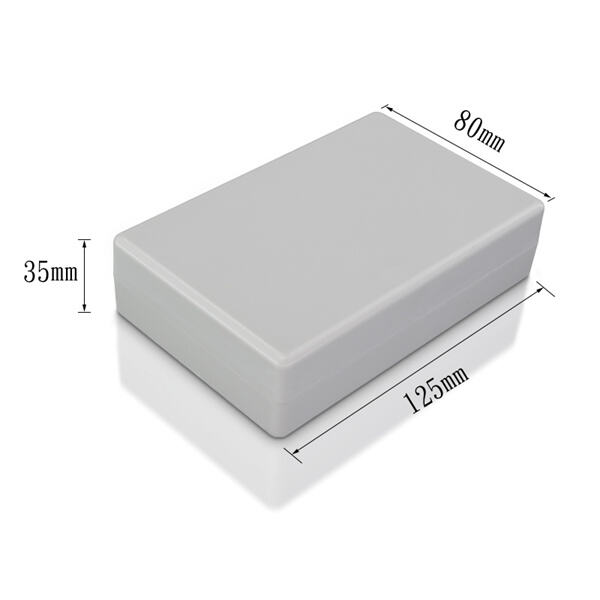

complete product line, ranging starting plastic boxes, aluminium enclosures sheet metal housings. offer CNC precision machined components, standard products OEM custom products, meet different needs different customers. Metal plastic cases utilized various industries applications, including construction, electronic equipment medical equipment, . matter need tiny robust case protect USB larger, rugged case protect power tools, have solution.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy