Hello, children! Have you ever thought about the material that is utilized in the cases or covers of your electronic gadgets? The material is called electronic housing plastic. Hongfa Shunda plastic housings is where internal components of Electronics like circuits and chips are housed. Plastic is what makes your devices tough, lightweight and convenient. You likely already know this, but electronic housing plastic possesses some exceptional properties and is more versatile than other materials. This article will investigate the concept of plastic electronic casing and five ways it transforms the electronics industry.

Specially hardened plastic is utilized in the electronic casing of vehicles. This rough terrain shields electronic parts from dust, chemicals, or falls while enduring varying temperatures and humidity levels. Just think about how vulnerable your electronic device would be without this shield! There are various types of Hongfa Shunda plastic electronics housing specifically created to meet the unique needs and specifications of different electronic devices. Smartphone: Thin, lightweight, and transparent plastic is used for the screen and buttons to be visible. Laptop: Thicker and more durable plastic is used to provide strength for protecting the keyboard, hard drive, and other sensitive components.

One important thing to note is that electronic housing plastic greatly impacts various aspects of the electronics industry. The extensive production process is where this makes a notable impact. Plastic, being more malleable than metal, is also easier to shape and 3D print, making it a cheaper option for bulk production. It is shaping in ways that optimize the packaging capacity of delicate electronic components to ensure proper airflow, enhancing their performance and lifespan. Moreover, Hongfa Shunda electrical plastic housing have the ability to incorporate various design elements such as waterproofing, scratch resistance, and anti-static properties to enhance the user experience. These features allow electronics to be used in a wide range of conditions, from outdoor activities to industrial environments. Uncovering Different Advantages of Plastic Electronic Enclosures in Today's Technology. Plastic housings are commonly used in many modern technological devices. Firstly, it reduces the weight and size of devices, thus improving their portability and convenience. Secondly, the thermos can have a stylish and appealing appearance because of the increased flexibility provided by a plastic housing. Finally, electronic housing made of plastic enhances device functionality by providing exceptional thermal conductivity and isolation features that minimize electromagnetic interference and lower power usage. Furthermore, using recyclable materials to produce wood is also a sustainable method. Therefore, the plastic housing for electronic devices is a key component for promoting a sustainable lifestyle that incorporates technology.

Currently, plastic casing has enhanced the performance and reliability of electronic devices. The durable plastic case, designed to safeguard the device, is not only strong enough to withstand tough conditions but also made practically indestructible through the process of over molding. Primarily, devices such as smartphones, tablets, and laptops, which are constantly used, are the most notable ones that venture out into the world and return. Made with tough plastic casing to prevent daily scratches, damage, and dirty fingerprints. Hongfa Shunda extruded aluminum housing further cuts down labor expenses by reducing the amount of maintenance needed. Furthermore, the durable plastic casing offers defense for electronic parts from environmental dangers like moisture, UV rays, and various forms of physical damage, which is equally important for heavy usage in harsh conditions.

The continuous expansion of plastic e-housing is itself a groundbreaking innovation. At the same time, scientists and engineers are still developing new plastic technologies to enhance the advantages of plastic used in electronic housings. Like, are there more effective ways to recycle plastic, can we create plastics that can repair themselves, or generate electricity from plastic? This will be achievable through advanced plastic technologies utilized to connect electronic devices, enhancing their intelligence, improving performance, and increasing interactivity. The plastic material, when combined with sensors, LEDs, or touch controls, can create a device that is less tactile but more energy efficient. Hongfa Shunda aluminum housing offers a smooth user experience, while also introducing users to additional features. In conclusion, electronic housing plastic is a fantastic material that transforms the look of the electronics industry. It offers essential backing for electronics, increased strength and adaptability in manufacturing and design, improved features and user satisfaction, while also allowing for advancements in eco-friendly technology. As technology progresses, we can expect electronic housing plastic to offer increasingly beneficial and advanced features in the future.

Hongfa Electronic housing plastic always put quality first every spot, from creation product purchase raw materials, monitoring each process 100% appearance inspection before shipment packaging, with highest level effort ensure every item purchased customer qualified high quality.

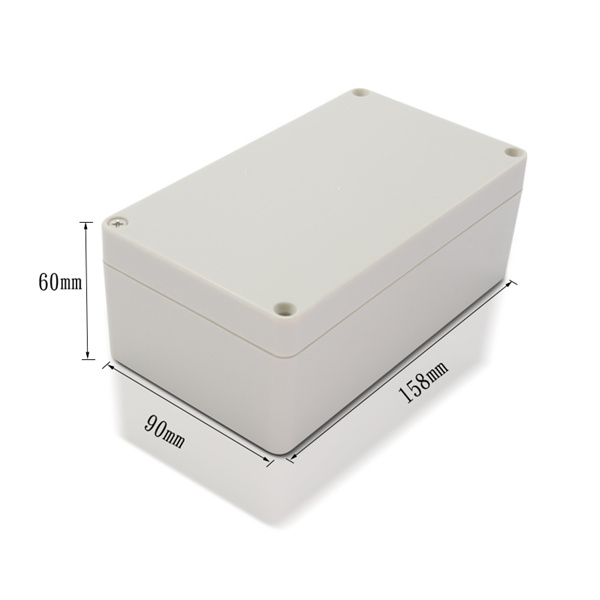

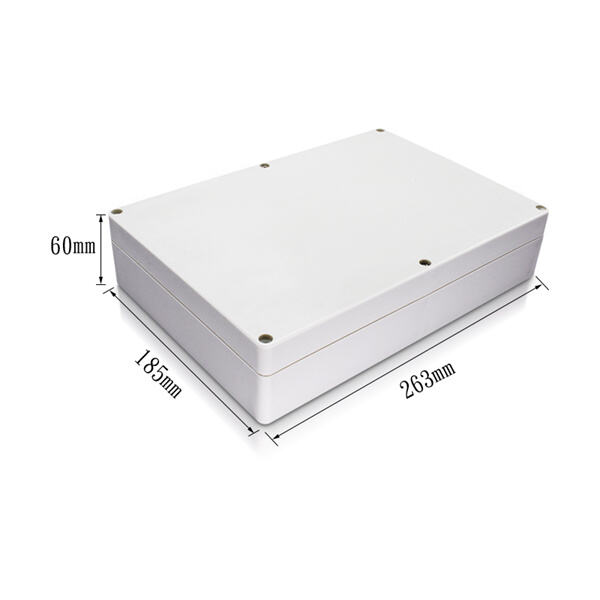

complete product line, ranging starting plastic boxes, aluminium enclosures, sheet metal housings CNC precision machined components, standard products custom-designed OEM products meet various requirements different customers. Our plastic metal cases ideal assortment industries uses include construction, electronics medical equipment, construction, many more. No matter you need tiny, durable case your USB large robust case protect power tools We have solution you.

team made up highly-skilled engineers, technicians craftsmen years experience knowledge Electronic housing plastic. pay attention every little detail ensure product exceeds highest quality high-precision standards

We tailor solutions address clients' unique requirements. Electronic housing plastic, assembly machining, work closely clients create solutions exceed expectations. From CNC cutting machining sheet metal fabrication welding we provide wide assortment manufacturing capabilities support various industries applications. wide range services allows manage large-scale projects conception completion.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy