Sheet Metal When it comes to building things out of metal, one of the most popular materials is sheet metal. It is thin and malleable, which is fantastic for producing many products, from car parts to appliances and even toys. But did you know how to make sheet metal products extra good? It is called the optimal design of sheet metal forming technology. This can help make products stronger, perform better and look better.

Optimizing Sheet Metal Design

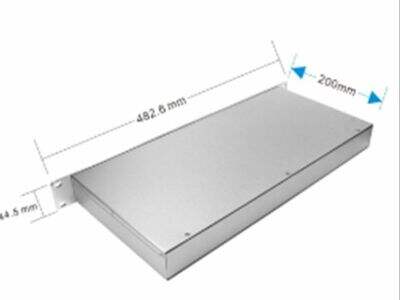

The process of optimizing sheet metal design begins with the design of how the metal is to be cut, formed and bent. Engineers have special computer programs to help them visualize how everything will be created. This aid enables them to ferret out issues and facilitstes the process.

One key factor in optimization is the way in which the sheet metal is cut. According to engineers, when the cut is planned carefully, they can use less metal and better-fitting parts. It saves money and reduces waste, which benefits the environment.

How to Get the Most from Your Sheet Metal Processes

There are quite a few tricks to make the most of sheet metal enclosure processes. One popular approach is called nesting. That could mean fitting various shapes together so all can be cut from one piece of metal. That is also helping to cut waste and streamline the process.

Another smart approach is to use the right tools and machines for the play. Engineers can produce more precise and high-quality products through the best equipment. Not only does this make the final product more attractive, it also helps preserve the product for longer.

Advantages of Sheet Metal Design Optimization

There are several advantages to streamlining Sheet Metal Enclosure design. One huge benefit is in saving companies time and money. By streamlining the process and eliminating waste, companies can produce products at a faster pace and reduced cost.

Secondly, it is also possible to improve the quality of the manufactured part with the optimierung. Then, when the engineers methodically design each of those steps, the result is more durable, reliable and pleasant to look at. This is useful for businesses as it means more people are attracted to the company.

Optimizing the Processing of Sheet Metal and Other Materials

Sheet metal processing can be better in many aspects through the principles of optimization. Efficiency is one easy win. By codifying each step, engineers can spend less time and energy creating a product. This enables companies to work faster and make more money.

Optimization is also a way to help ensure that products are more consistent. It is a more accurate process because special computer programs enable engineers to design parts in a more advanced way. Not only does this look good on the finished product, it also makes sure that all of the parts will fit properly together.

Application of Optimization in Sheet Metal Technology

Process Optimization We at Hongfa Shunda understand the importance of optimization in sheet metal processing. That’s why we build with the most advanced tools and methods to create products that are strong, efficient and beautiful. By being thoughtful about every single step, we can create great product demanded by customers.