The world is moving quickly and people are becoming more thoughtful about how they take care of the environment. Lots of plastics don’t decompose very quickly and last in nature for hundreds of years. And it is life threatening to animals, plants and human beings. That is why companies like Hongfa Shunda are hunting for superior materials, so they can make things like enclosures. Enclosures are the housing or covering for electronic equipment or machinery. Making these enclosures out of biodegradable plastics seems like a smart idea to save the planet.

Enclosure processing:

Biodegradable plastics have a lot going for them when it comes to packaging that protects products. They are useful for forming green packaging that is wound able safely about goods, without pollution. For instance, aluminum amplifier enclosure can offer the same protection as conventional plastic foams or wraps but dissolve after being discarded. That means less garbage in landfills and oceans. At Hongfa Shunda, we believe that these materials hold a lot of promise in the packaging enclosure space.

Small appliance enveloped in a biodegradable plastic

This sort of packaging demonstrates a company that cares about the environment and is inclined to help. Hongfa Shunda said it thinks this will catch on fast as governments and customers demand greener choices. Moreover, biodegradable plastics are often produced from plants or other natural sources, in which case they are renewable. Even if some people may consider biodegradable plastics costly, the avoidance of pollution and environmental protection is worth its cost. With advances in technology such materials are becoming increasingly inexpensive and straightforward to process. Hongfa Shunda is poised to apply these advances to producing packaging that will be safe, strong and earth friendly.

Biodegradable plastics seem to be the most suitable candidate

These materials can also be recycled or composted, enabling the circle of waste to be broken. Some enclosure manufacturer do require special conditions to degrade although new formulations are improving rapidly. At Hongfa Shunda, we take pride in offering these green alternatives to our customers.

How to Guarantee Quality of Biodegradable Plastic Box

Wholesale buyers are interested in product that looks good, lasts long, and works well. For its part, companies such as Hongfa Shunda even introduce special measures in the testing and quality control of their biodegradable plastic enclosures to ensure that all those needs are met. The first is to be extremely picky about the raw materials. Biodegradable plastics need to be sturdy but have a safe afterlife in the environment.

Enclosure Processing Under New Environmental Standards

Enclosures are even likelier to be made of biodegradable plastics as countries and companies seek to protect the environment. New environmental laws and regulations promote the use of materials that are friendlier to the planet. Conventional plastics can last hundreds of years before they begin to break down polluting the environment and endangering animals. Biodegradable plastics, meanwhile, can naturally decompose in a short period of time thus minimizing waste and pollution.

This businesses biodegradable plastics in their cases

The use of these plastics sends the signal that it is important to businesses to care about the environment and to minimize their impact on our natural world. This is significant as plastic pollution is one of the largest environmental problems currently facing the planet. By transitioning to biodegradable plastics, enclosure companies like Hongfai Shunda can be part of the solution to preserving wildlife and maintaining a cleaner planet.

How to Incorporate CreatureSafe Plastics Housing Manufacturing

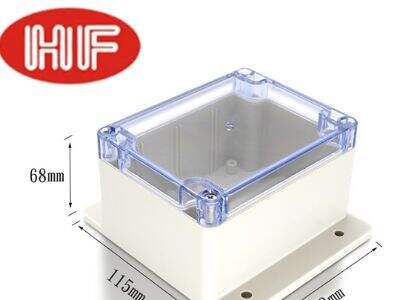

In addition, incorporating waterproof battery box into existing enclosure production lines may be a sensible way to make greener products without having to reinvent the wheel. Firms like Hongfa Shunda understand the importance of keeping production running smooth and efficiently through this material shift. The first is to review existing machines and processes, determining if they are suitable for working with biodegradable plastics. These plastics may have reduced melting point or flow characteristics compared to standard plastics.

Table of Contents

- Enclosure processing:

- Small appliance enveloped in a biodegradable plastic

- Biodegradable plastics seem to be the most suitable candidate

- How to Guarantee Quality of Biodegradable Plastic Box

- Enclosure Processing Under New Environmental Standards

- This businesses biodegradable plastics in their cases

- How to Incorporate CreatureSafe Plastics Housing Manufacturing