They protect everything from dust, water and other external threats. Designing and constructing these enclosures require thoughtful planning and dexterity. You need to select the right metal, determine the shape and size, and ensure it fits like a glove. At Hongfa Shunda, we have been in the business of manufacturing durable sheet metal enclosures that stand up to many different forms for years.

What Wholesale Buyers Need to Learn

When you’re buying large quantities of sheet metal enclosure enclosures, it’s not only about the price. Quality matters a lot. Simply, many buyers fail to see the importance of material. For example, steel and aluminum are the most popular but they have different properties. Steel is stronger and tougher but heavier; aluminum is lighter and resists rust better. And then of course, the thickness of the metal also is a factor to consider for its longevity and durability.

How To Get Trusted Sheet Metal Enclosure Suppliers for Bulk Orders

It can be difficult to locate a great manufacturer who can handle large orders when it comes to big sheet metal enclosure projects. You need someone who can make plenty of units with no errors and no delays. Hongfa Shunda has no trouble with that. Shopping for manufacturer When you are looking for a manufacturer to work with, see if they have the latest machines. A suite of fine tools aid in the fashioning of enclosures with precise contours and crisp edges.

Why Sheet Metal Enclosures are So Important for Industrial Use

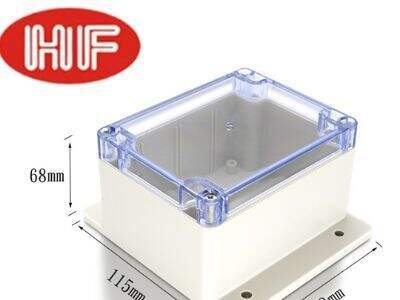

Sheet Metal Enclosures Sheet metal enclosures are critical for a wide range of industries as they protect machinery and sensitive electronic equipment. Such enclosures weave together thin enclosure sheet metal that are molded, folded and seamed around the objects they secured. At Hongfa Shunda, we recognize that these enclosures protect your valuable equipment from dust, water, spurts of heat and even occasional whacks. Many machines are subjected to damp conditions in factories or the open air. Without a solid cover overhead, parts are liable to break or fail to work correctly, which can cost time and money.

Sheet Metal Enclosure Design Common Problems

There are common issues that can occur if not factored into the design of sheet metal electrical box enclosures at times. We’ve discovered, through trial and error, what these problems are and how to prevent them from happening to make sure each and every enclosure performs optimally. If the case is not machined to precise dimensions, it could end up too slack or overly tight. This may lead to movement or damage of the internal parts.

Ensure Ultimate Product Protection through Casing Design

Designing a sheet metal enclosure to hold product in place, and protect it, is the process of considering a multitude of small details. At Hongfa Shunda, we concentrate on designing for the best possible protection while keeping the enclosure simple to manufacture and use. One important way to do a better job of protecting them is by choosing the right materials. Steel or aluminum type materials are popular choices as they aren’t easy to dent or puncture.