Why are PCB Enclosures Necessary in Electronics Designs?

If you are developing a cool electronics project, the last thing they always seem to care about is PCB enclosures. These aforementioned containers are very huge in keeping your electronic unit secure from many types of disasters. Read on to know why PCB enclosures are important; and how you can make your customers go wow with them!

One of the Major benefits: Ensuring that your electronic parts are protected from substances such as dust water and other foreign objects.

EMI Shielding :Provide the solution for your electronics to improve performance of electrical interference with proper shielding

Aesthetic: Make your projects look better with a nice, professional-looking shell

Simplify connections and aid maintenance: ensure the project is easy for people like you to connect, involve in conversations rapidly -_Filter Candidates on Project Open Tasks_

Safety: To ensure a safe environment by avoiding contact with live electrical components.

Vision: Build a strategic vision before going into the design process.

Dive Into the World of Custom Enclosures with Cutting Edge 3D Printing Techniques

Select Quality Materials: Choose long-lasting and proven component materials for your design to ensure it is safe.

Prototype Testing: ensure that your design is up to the mark with project requirements.

Please Be Creative: Use your imagination in the creation of an innovative and personalized shelter that stands out.

Build it to last: Choosing robust materials that provide the necessary protection for your electronic component

Heat Management: For projects needing to dissipate heat, look for thermo conductive materials.

Aesthetics: Choose materials that can be easily modified to look the way you want.

Play withcolors and textures :Try different color palettes and add in some textured surfaces to hit the right look

Adding Cutouts: Add good functional cutouts for air flow and to give a peek inside the project.

Using LEDs: Add an air of the future by including LED lighting in your enclosure design.

Pushing The Boundaries of Acceptable Shapes: Dare to do the different and explore some irregular shapes on your design.

5. Choosign a Drone or Robotics Project Enclosure

Size and Weight: Same as power, whatever enclosure size/weights exist in the real world should be your first guide.

In instances of drone use, select lightweight but durable materials by all means.

Component accessibility - Ensure that internal components are easily accessible for repairs and upgrades (easier to get running)

PROTECTION: Ensure proper protection from environmental exposures to prevent project degradation.

To summarize, the significance of PCB's enclosures to electronics projects cannot be exaggerated. They combine durability, appearance and performance qualities with that all-important safety factor they are an indispensable ingredient in ensuring your project succeeds. Creating the perfect PCB enclosure is how you unleash your projects, whether youre brand new to DIY or an electronics pro.

Hongfa Shunda placed product quality first place, design product, purchase raw materials, control step along 100 quality inspection appearance prior shipment packaging. We make greatest pcb enclosure ensure item purchased customer high standard.

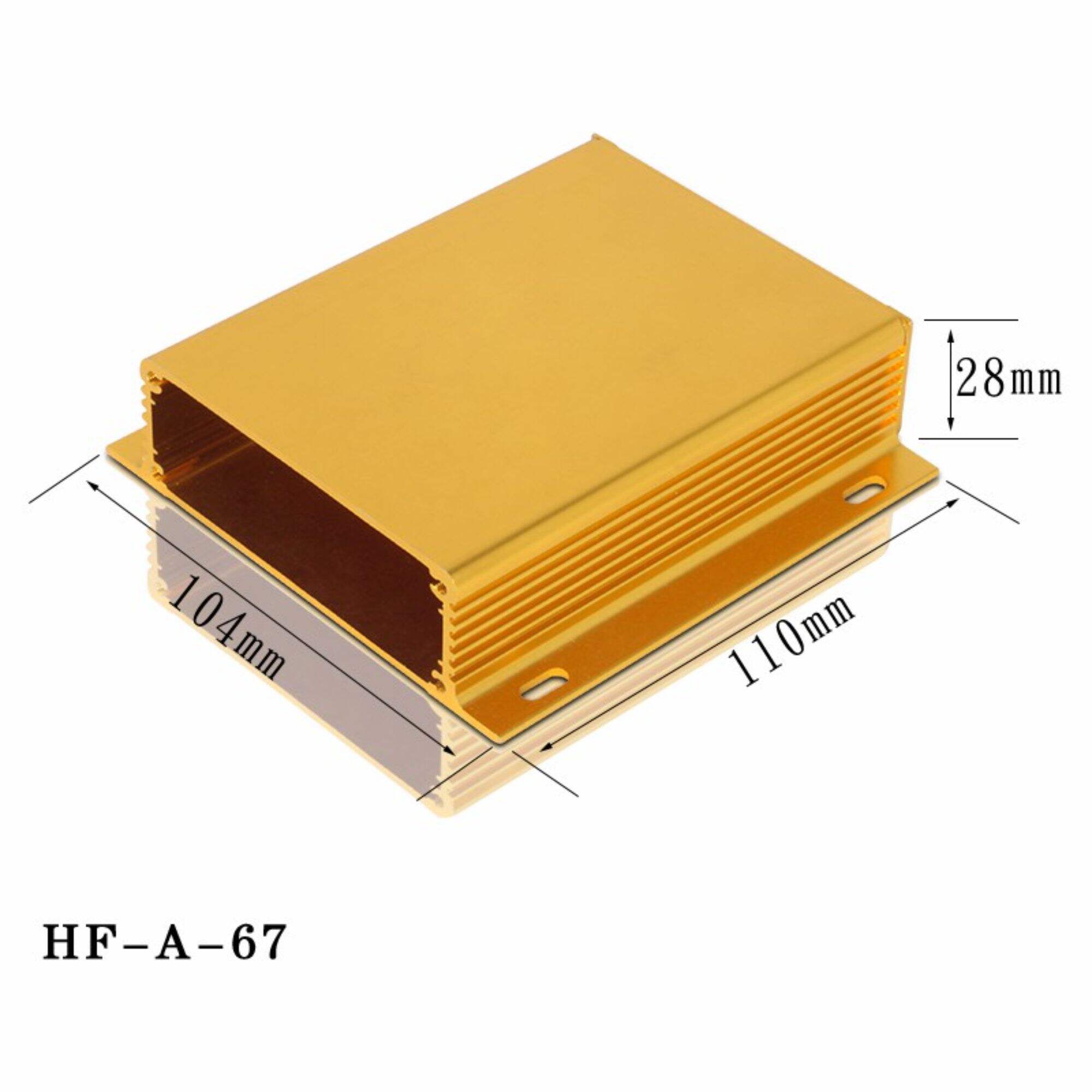

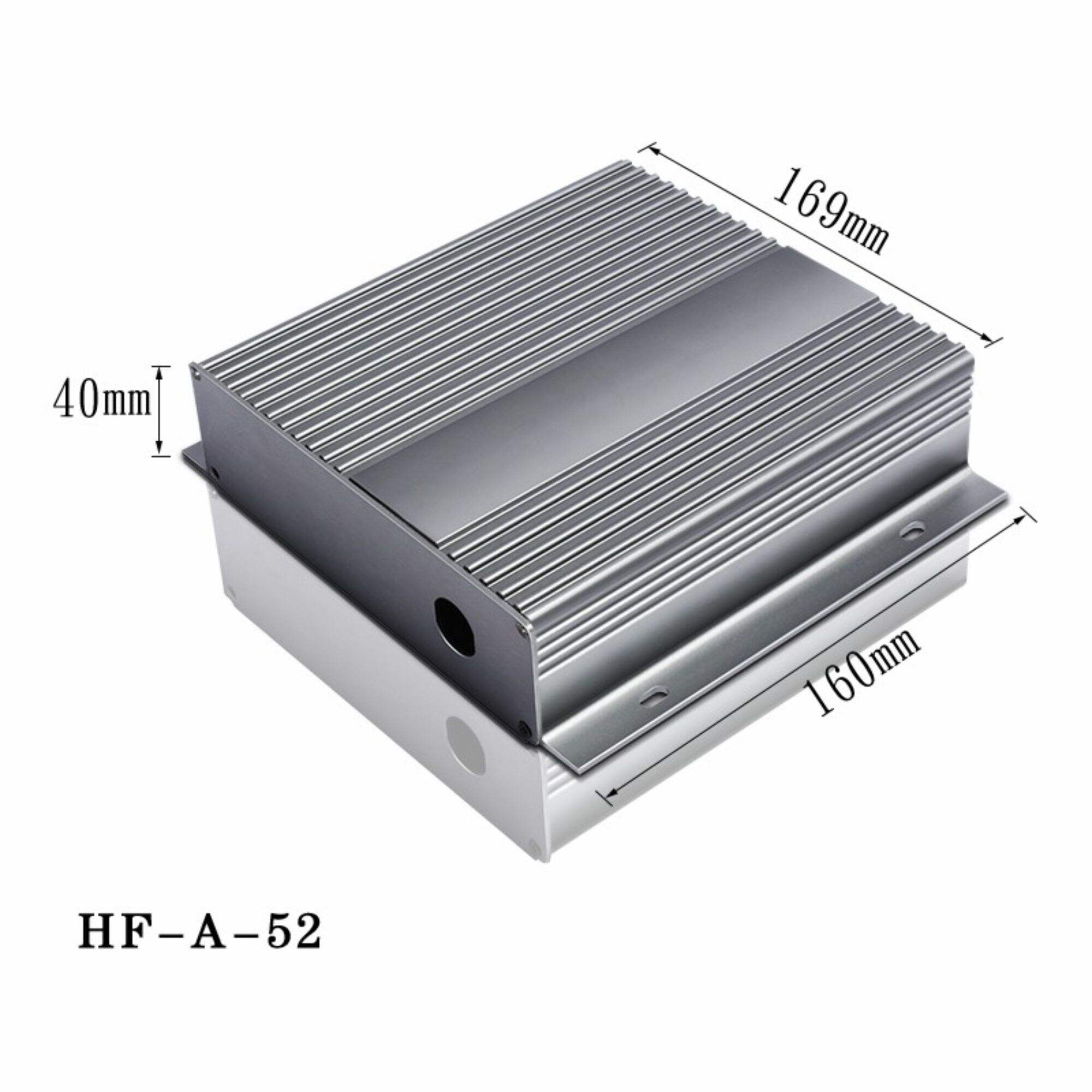

Complete product lines, starting plastic boxes, aluminium enclosures, sheet metal housings CNC precision machined parts range standard items custom designed OEM products meet different needs various customers. Metal plastic cases suited wide assortment industries uses which include construction, electronics medical equipment, many more. We have solutions your requirements, whether you need strong, small case USB huge, tough case power tool.

manufacturing facilities pcb enclosure cutting-edge technology advanced machinery, enabling make high-quality precision components unmatched precision efficiency. team consists highly experienced engineers, technicians craftsmen who possess years experience expertise metalworking. pay close attention every single detail ensure product exceeds highest quality precise standards.

We provide customized solutions satisfy customers' individual pcb enclosure. comes prototyping, machining, assembly, work close collaboration clients create solutions exceed expectations. From CNC laser cutting machining, sheet metal fabrication welding provide broad range manufacturing capabilities accommodate variety industries applications. manage complex projects beginning finalization, using full range service.

Copyright © Shenzhen Hongfa Shunda Mould Co., Ltd. All Rights Reserved - Privacy Policy